Product Description

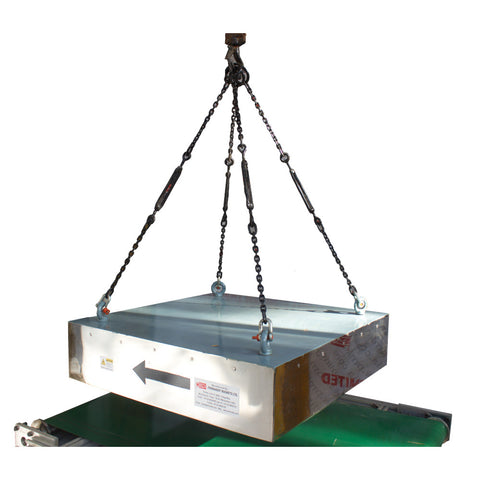

The Self Cleaning Filter series is the latest generation of self- purging high intensity magnetic filters for high flow, high contamination industrial applications.

The Self Cleaning Filter model will have 2 chambers, Fluid enters the inlet chamber where primary filtration takes place. The partly treated fluid flows into a second chamber where it is slowed so that the final filtration treatment can take place. It then returns to the process.

Installing Self Cleaning Filter will improve your manufacturing effectiveness and reduce operator intervention.

Using fully filtered fluid, free from micron sized particles will:

- Improve surface finish

- Improve fluid flow

- Cut costs on scrap reduction

- Reduce downtime

Typical Applications

- Grinding

- Honing

- Milling

- Fine finishing

- Liquid Pharma products

- Liquid Chemicals

- Liquid Food products

- Lubricants

- Coolants

- Hydraulic oils

- Slurries

Schematic Drawing for Self Cleaning Magnetic Filter

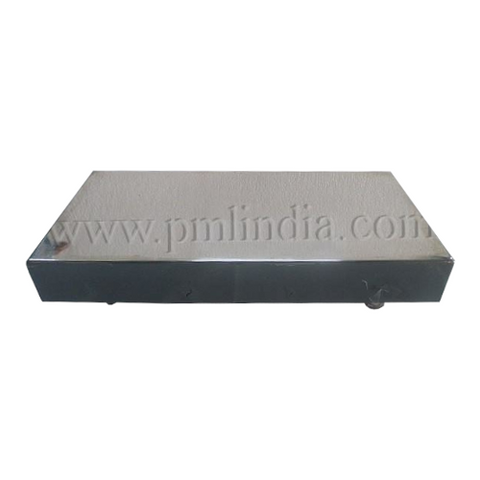

Standard Self Cleaning Filter

| Standard Self Cleaning Filter | |||||

|---|---|---|---|---|---|

| Model No. |

A(mm) Height |

B (mm) Diameter |

C (mm) Flange CTC |

No. of Magnetic Elements |

Recommended For Flow Rates* Liters/ per min |

| SCF1 | 835 | 200 | 540 | 6 | 500 |

| SCF2 | 1200 | 250 | 640 | 8 | 1200 |

| SCF3 | 1200 | 300 | 740 | 12 | 2000 |

Cleaning Process

A signal from your control system activates the outlet valve (not included) so fluid is redirected to a purge tank or reclamation unit (available as an option), then the centrally positioned pneumatic cylinder withdraws the magnetic elements from the filter

When the contamination has been purged the magnetic elements are reinserted and the outlet valve is returned to position, bringing the unit back online. The complete cleaning cycle takes 10-15 seconds depending on fluid type and filter location.

Self - Cleaning Magnetic Filter Systems have the following features:

- The magnetic filters can be installed easily in the fluid flow line

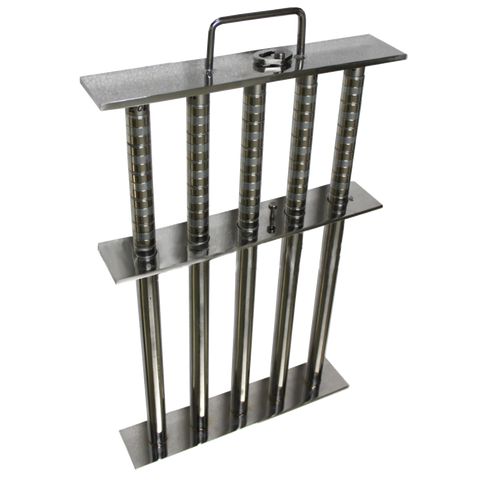

- They give complete magnetic protection by attracting iron particles as fine as 10 microns into the magnetic trap

- The magnets are installed in polished condition for the higher life of the rods and ease of cleaning

- For different flow rates, different sizes of magnetic filters are available

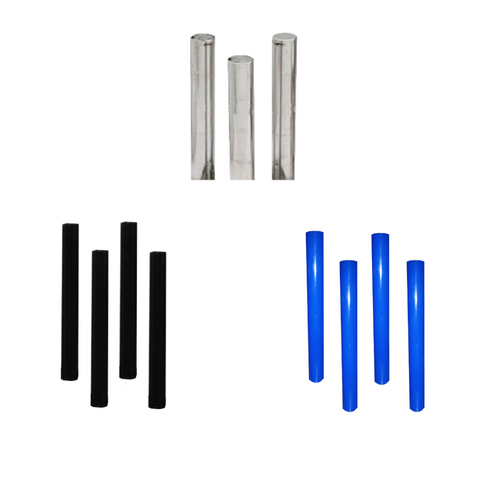

- High-Intensity Rare Earth Magnets or Low-Intensity St. Ferrite Magnets are used depending upon the user's requirement

- Normally these filters are designed to take up pressures 5kg/ cm2. They can be designed to withstand higher pressure

- Maximum operating temperature 80ᵒC. They can be designed to work at temperatures as high as 200°C

- Self purging

- No maintenance

Self cleaning Type Permanent Magnetic filters are used for the separation of iron particles from liquid.

The Magnetic filter is supplied with the pneumatic cylinders, FRL Unit & Timer with Operating button for controlling the cleaning.

Product Features:- Self cleaning, air operated, for remote installations, frequent cleaning, or fully automated system

- Removes Micron size iron contamination

- Wear resistant tube treatment and special wiper seals for abrasive products

- Customized Filter designs available

- FDA approved Food grade gasket material

- Finish and welding treatments available for food and sanitary grade applications

- Matching companion Flanges for easy installation.

- 304/316 stainless steel construction

- The air-actuated stripper seal assembly discharges collected tramp metal into a catch pan as the drawer opens.

- High-intensity Drawer Type Grill with Maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).

Why PML Self Cleaning Filters?

- 60 years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Filters are available in 11,000 Gauss for operating temperature up to 120°C and 9000 Gauss at an operating temperature of 250°C

- Super high-intensity magnetic rod also available with gauss value 12,000 for maximum operating temperature up to 80ᵒC.

- Customized design

- Magnetic Filters are hydraulically tested to check leakage at welding joints and sealing points.

- PML offers comprehensive Magnetic Filtration Systems using 2/3 Magnetic filters in series to ensure output contamination to a minimum PPM level.

- Services such as magnetic calibration/Audit are available