Product Description

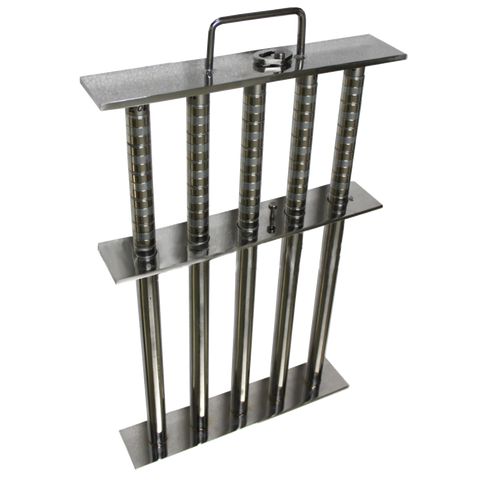

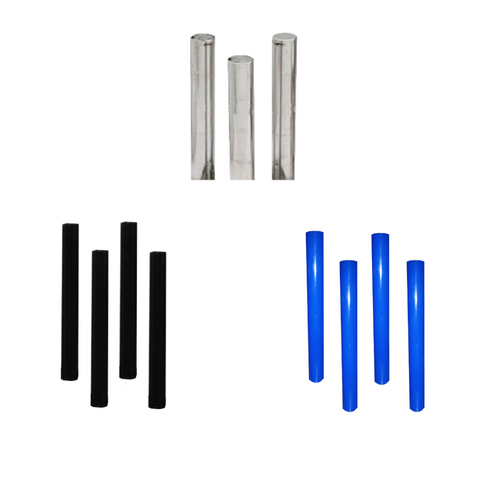

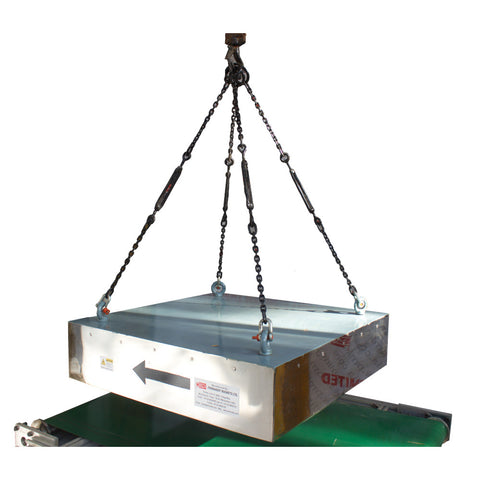

Drawer Type Permanent Magnetic Grills are used for the separation of iron particles from dry, granular or free-flowing products/materials. Drawer Magnetic Grills are made by using stainless steel having (Round or square or rectangular) with magnetic rods mounted on the drawer.

The Drawer Type grills are made up of magnetic elements, which are fitted in a drawer and is moving in a housing. Magnetic Elements are made up of hard ferrite ceramic magnets or high-intensity rare earth magnets ( NdFeB ). All the components are made up of Stainless Steel 304/316 material. The overall construction of the magnetic grills can also be made as per the customer specification and sizes

The grills are efficiently utilized if contamination is within 1% to 1.5% by weight. For higher levels of contamination Drawer Grills or Multi Drawer Grills should be used.

Low-Intensity Magnetic Grill having Gauss value of approximately 2,500 Gauss are ideal for trapping contamination such as Nuts, Bolts, Screws, broken washers, etc. these grills are designed to attract larger iron pieces from a relatively larger distance.

Medium Intensity Magnetic Grill having Gauss value of approximately 6,500 Gauss are used where the contamination is in particle form, however, there may or may not be a continuous flow of material to be separated. The contamination size may be as low as 150 microns but not lower than that. The material should be free-flowing and non-sticky.

High-Intensity Magnetic Grill having Gauss value of approximately 11,000 Gauss are employed at locations where the separation of contamination particles as small as 1 micron is required. These grills have been designed to attract super fine particles from the carrier material.

Super High-Intensity Magnetic Grill having Gauss value of approximately 12,000 Gauss are available. In all the four classes of the grill, it is necessity to clean the grills at regular intervals. It is recommended to clean the grill thoroughly before every pass (or as scheduled as per users' requirements and experience). More accumulation of Iron particles for a long time will reduce the effectiveness of the grill. For the highest attraction, the grill needs to be fully clean.

Standard Size Drawer Type Magnetic Grill:

Single Drawer Magnetic Grill Drawing:

| High-intensity Single Drawer Magnetic Grill (11,000 ± 500 Gauss) | |||||

|---|---|---|---|---|---|

| Model No. | A (mm) Dia. |

B (mm) HT. |

C (mm) |

D (mm) |

No.Of Magnetic Elements |

| HSDG1 | 100 | 165 | 156 | 173 | 3 |

| HSDG2 | 150 | 165 | 206 | 223 | 4 |

| HSDG3 | 200 | 165 | 256 | 273 | 5 |

| HSDG4 | 250 | 165 | 306 | 323 | 6 |

| HSDG5 | 300 | 165 | 356 | 373 | 6 |

| HSDG6 | 350 | 165 | 406 | 423 | 7 |

| HSDG7 | 400 | 165 | 456 | 473 | 8 |

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model No. | Flange O.D.E(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.F(mm) |

| HSDG1 | 228.6 | 19.0 | 8 | 190.5 | 6 |

| HSDG2 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| HSDG3 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| HSDG4 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| HSDG5 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| HSDG6 | 533.4 | 28.6 | 12 | 476.2 | 6 |

| HSDG7 | 596.9 | 28.6 | 16 | 539.7 | 6 |

| Super High intensity Single Drawer Magnetic Grill (12,000 ± 500 Gauss) | |||||

|---|---|---|---|---|---|

| Model No. | A (mm) Dia. |

B (mm) HT. |

C (mm) |

D (mm) |

No.Of Magnetic Elements |

| SHSDG1 | 100 | 165 | 156 | 173 | 3 |

| SHSDG2 | 150 | 165 | 206 | 223 | 4 |

| SHSDG3 | 200 | 165 | 256 | 273 | 5 |

| SHSDG4 | 250 | 165 | 306 | 323 | 6 |

| SHSDG5 | 300 | 165 | 356 | 373 | 6 |

| SHSDG6 | 350 | 165 | 406 | 423 | 7 |

| SHSDG7 | 400 | 165 | 456 | 473 | 8 |

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model No. | Flange O.D.E(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.F(mm) |

| SHSDG1 | 228.6 | 19.0 | 8 | 190.5 | 6 |

| SHSDG2 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| SHSDG3 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| SHSDG4 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| SHSDG5 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| SHSDG6 | 533.4 | 28.6 | 12 | 476.2 | 6 |

| SHSDG7 | 596.9 | 28.6 | 16 | 539.7 | 6 |

Standard Size Double Drawer Magnetic Grill Drawing:

| High-intensity Double Drawer Magnetic Grill(11,000 ± 500 Gauss) | |||||

|---|---|---|---|---|---|

| Model No. | A (mm) Dia. |

B (mm) HT. |

C (mm) |

D (mm) |

No.Of Magnetic Elements |

| HDDG1 | 100 | 250 | 156 | 173 | 5 |

| HDDG2 | 150 | 250 | 206 | 223 | 7 |

| HDDG3 | 200 | 250 | 256 | 273 | 9 |

| HDDG4 | 250 | 250 | 306 | 323 | 9 |

| HDDG5 | 300 | 250 | 356 | 373 | 11 |

| HDDG6 | 350 | 250 | 406 | 423 | 13 |

| HDDG7 | 400 | 250 | 456 | 473 | 15 |

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model No. | Flange O.D.E(mm) | Hole Dia. (mm) | No. Of Holes | Hole PCD(mm) | Flange THK.F(mm) |

| HDDG1 | 228.6 | 19.0 | 8 | 190.5 | 6 |

| HDDG2 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| HDDG3 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| HDDG4 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| HDDG5 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| HDDG6 | 533.4 | 28.6 | 12 | 476.2 | 6 |

| HDDG7 | 596.9 | 28.6 | 16 | 539.7 | 6 |

| Super High intensity Double Drawer Magnetic Grill (12,000 ± 500 Gauss) | |||||

|---|---|---|---|---|---|

| Model No. | A (mm) Dia. |

B (mm) HT. |

C (mm) |

D (mm) |

No.Of Magnetic Elements |

| SHDDG1 | 100 | 250 | 156 | 173 | 5 |

| SHDDG2 | 150 | 250 | 206 | 223 | 7 |

| SHDDG3 | 200 | 250 | 256 | 273 | 9 |

| SHDDG4 | 250 | 250 | 306 | 323 | 11 |

| SHDDG5 | 300 | 250 | 356 | 373 | 13 |

| SHDDG6 | 350 | 250 | 406 | 423 | 13 |

| SHDDG7 | 400 | 250 | 456 | 473 | 15 |

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model No. | Flange O.D.E(mm) | Hole Dia. (mm) | No. Of Holes | Hole PCD(mm) | Flange THK.F(mm) |

| SHDDG1 | 228.6 | 19.0 | 8 | 190.5 | 6 |

| SHDDG2 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| SHDDG3 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| SHDDG4 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| SHDDG5 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| SHDDG6 | 533.4 | 28.6 | 12 | 476.2 | 6 |

| SHDDG7 | 596.9 | 28.6 | 16 | 539.7 | 6 |

Customized Double Drawer Type Magnetic Grill:

Industries using Magnetic Grill:

- Plastic

- Food Products. (Sugar, Coffee, Tea, Grains, Pulses, Flour, Spices, Milk, etc.)

- Pharmaceutical

- Chemical

- Ceramic

- Colors / Paints

- Pigments

- Ink

- Refractory

- Mineral

Other Types Of PML Magnetic Grill:

Product Features:

- All construction element of the grill magnet are in S.S. 304/ S.S.316

- Customized grill designs and magnetic grid designs available.

- Medium and High-intensity Grills with Maximum operating temperature 250ᵒC also available.

- High-intensity Drawer Type Grill with Maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).

Why PML Magnetic Grill?

- 45+ years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Grills are also available with 10,000 Gauss for operating temperature up to 200°C

- Easy to clean and no maintenance cost and preventing expensive shutdown and delays for equipment down the process line

- No power cost

- Installation of these grills improves product quality thereby enhances product value and helps in meeting FDA and other government/customer regulations on iron contamination levels

- Services such as magnetic calibration/Audit are available

- PML also makes customized design and self-cleaning grills

Some of PML’s valued customers:

- Hindustan Unilever (All plants in India)

- Cipla Ltd (All plants in India)

- H & R Johnson (India) Ltd

- Lucid India Ltd, Jodhpur

- Tata Tea Ltd (All plants in India)

- Pidilite Industries (Vapi)

- Hindustan Inks & resins Ltd (Vapi)

- Sudarshan Chemicals Ltd (Roha, Mahad, & Pune plants)

- Mazda Colors Ltd (Vapi)

- Dhiraj Enterprises

- Anupam Colors Pvt Ltd

- JBF Industries Ltd (Silvassa)

- Clariant Chemicals Ltd (Thane)

- Kerala Chemicals & Proteins Ltd (Kochi)

- Nepal Lever Ltd (Nepal)

FAQ for Magnetic Drawer Type Grill

- 1) How to clean it?

- Ans - Remove the magnet drawer from the housing & with the help of clothe wipe out the iron from magnetic rod. Pressurised air can also be used to clean the iron contanimation of the rod. Hot water (temperature not exceeding 60 degree celsius) can also be used.

- 2) Can it be used for liquid products?

- Ans - No. It can be used for granular, dry, free flowing powder like products only.

- 3) Is electricity required to operate it?

- Ans - Magnetic grill consists permanent magnets therefore it does not require power supply.

- 4) Is it suitable for lumpsy or sticky material.

- Ans - No. Sticky or lumpsy material will start bridging on the magnetic rod so it can block the material flow. We advise to use PML Magnetic Rota Grid / Magnetic Chute for lumpsy / sticky / Viscous material.

- 5) Can it be used for horizontal material flow?

- Ans - No. It is used for vertical flow of material only.

- 6) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 7) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 8) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 9) What will be the minimum space / height required for installing drawer type grill?

- Ans - For single drawer type grill minimum height 165mm is required & for double drawer type grill 250mm is required.

- 10) What is the standard of inlet / outlet flanges?

- Ans - We use ASA150 / ASA300 standard flanges. Customized grills also available with customize inlet / outlet.

Our Valuable Customers for Magnetic Drawer Type Magnetic Grill

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|