Magnetic Chutes are used for trapping and separating iron particles mixed with dry, granular or powdered materials. They are generally used where flowing material characteristics are sticky and non-free-flowing. They come with either Conical Magnets fitted on hinged doors or Magnetic Plates fitted on the sides. These systems are easy to clean and maintain.

Industries Using Magnetic Chutes:

- Plastics

- Food

- Spices

- Chemicals

- Dyes & Powder Pigments

Standard PML Magnet Chutes:

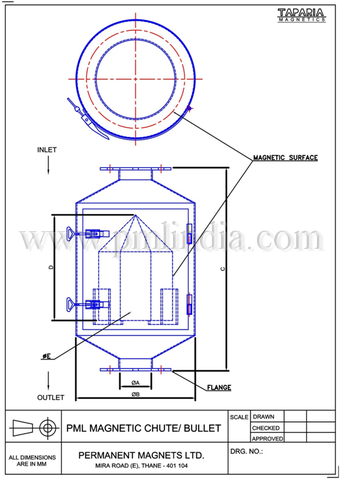

| Model | A (mm) | B (mm) | C (mm) |

|---|---|---|---|

| CB001 | 120 | 350 | 220 |

| CB002 | 150 | 350 | 250 |

| CB003 | 200 | 478 | 300 |

| CB004 | 250 | 478 | 350 |

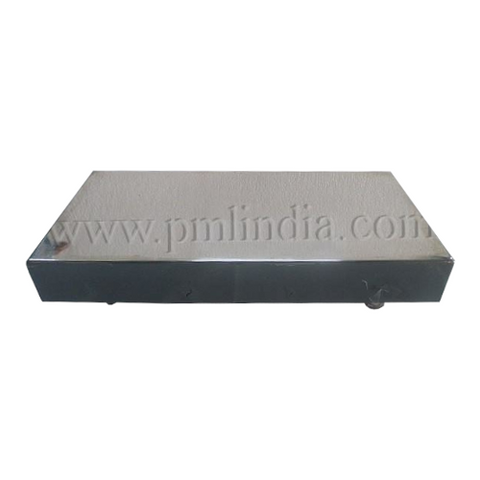

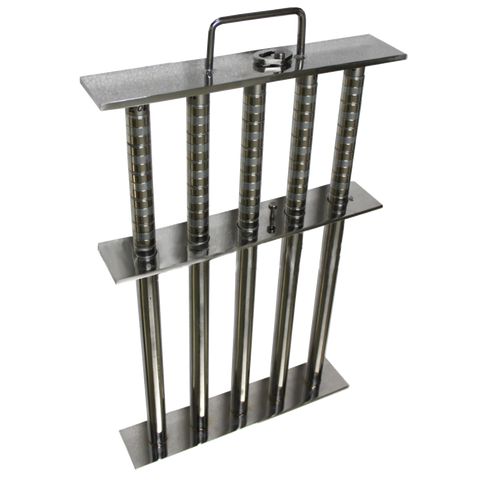

Construction:

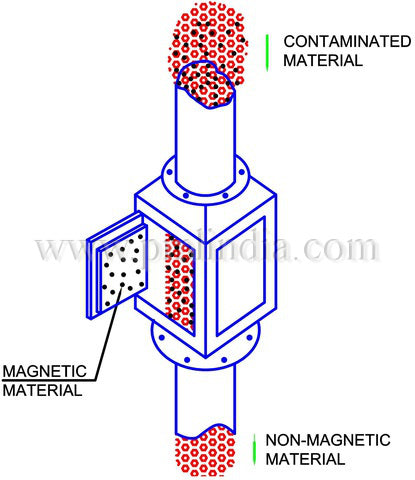

In a door type Magnetic Chute, the magnets are placed on the doors and in the Bullet type Chute, a conical shape magnet is fixed at the center of the chute.

The central Magnet is fitted on the hinged door and can be swung out for manual cleaning of arrested iron particles after the batch is over or at a decided frequency of cleaning. Inside the bullet magnet, there are guided strips that direct material onto the bullets' face.

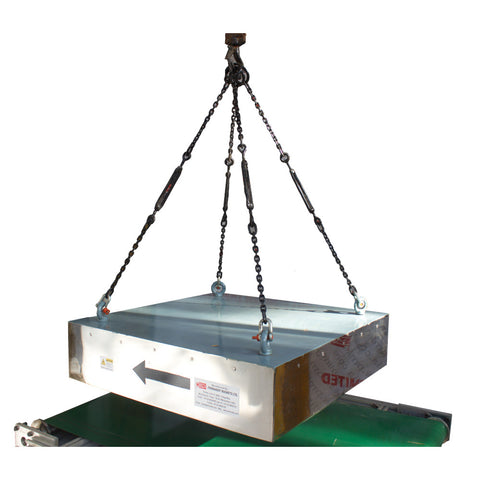

The chutes are generally placed vertically on the discharge ducts. However if required it can also be placed horizontally between the material flow lines. Such systems may call for suction.

Features:

Magnetic Chutes have following features:

- The magnetic Chutes can be installed easily in a flow line.

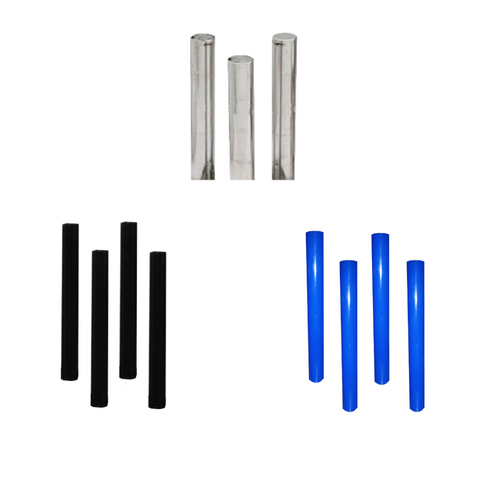

- Bullet conical type magnetic chute (4,500) gauss & bullet rod type magnetic chute (11,000 gauss) is also available for 80ᵒC.

- High-intensity Bullet Rod Type Magnetic Chute with 9,000 gauss value and maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).

- They give complete magnetic protection by attracting iron particles over the magnet surface by trapping particles as fine as 10 microns.

- The bullet magnet is installed in finished condition for the life of the bullet and ease of cleaning

- For different flow rates, the magnetic chutes of different sizes are available.

- High-Intensity Rear Earth Magnets are used fitting best to the user’s requirement.

How does it work?

The magnetic chute is placed in the flow path of the materials passing through the ducts, with the help of flanges. As the material flows through the chute, the iron contamination gets attracted to the magnetic surface and the non-magnetic material flows out of it without any disturbance.

Information required for the design of magnetic chutes:

- Size of the duct and the flange with which the chute has to be fixed

- Type of material and size of the particle

- Size and concentration of contamination

- Flow rate

Why PML Magnetic Chute?

- 45 years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Chutes are available with high intensity of 5000 Gauss

- Customized Design

- Services such as magnetic calibration/Audit are available

- Arrested iron particles can be easily removed manually

Some of PML’s valued customers:

- Hindustan Unilever (All plants in India)

- Cipla Ltd (All plants in India)

- H & R Johnson (India) Ltd

- Lucid India Ltd, Jodhpur

- Tata Tea Ltd (All plants in India)

- Pidilite Industries (Vapi)

- Hindustan Inks & resins Ltd (Vapi)

- Sudarshan Chemicals Ltd (Roha, Mahad, & Pune plants)

- Mazda Colors Ltd (Vapi)

- Dhiraj Enterprises

- Anupam Colors Pvt Ltd

- JBF Industries Ltd (Silvassa)

- Clariant Chemicals Ltd (Thane)

- Kerala Chemicals & Proteins Ltd (Kochi)

- Nepal Lever Ltd (Nepal)

FAQ for Magnetic Chute

- 1) Where it is used?

- Ans - Magnetic chute is used to separate iron from sticky, slurry & not free flowing materials. For Eg- Chocolate Manufacturing

- 2) How to install magnetic chute?

- Ans - Magnetic chutes are made to fit to the close pipelines & available with standard flanges for the inlet & outlet.

- 3) What is the installation position of magnetic chute?

- Ans - It should be installed vertically only.

- 4) How to clean magnet?

- Ans - The door is provided to housing to take out the magnets for cleaning. Magnet need to clean manually only. One can use pressurised air for ease of cleaning iron from magnet.

- 5) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 6) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) What are the types of inline Magnet?

- Ans - There are two types of Inline magnet (Magnetic Chute) available. A) Bullet type design with variations for 4500 gauss & 12000 gauss B) Plate type Magnetic chute with 4500 gauss

- 9) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 10) Is it suitable to catch heavy iron parts?

- Ans - No. It is made to catch small fine iron particle from slurry, paste like material.

Our Valuable Customers for Magnetic Chute.

|

|

|

|

|

|

|

|