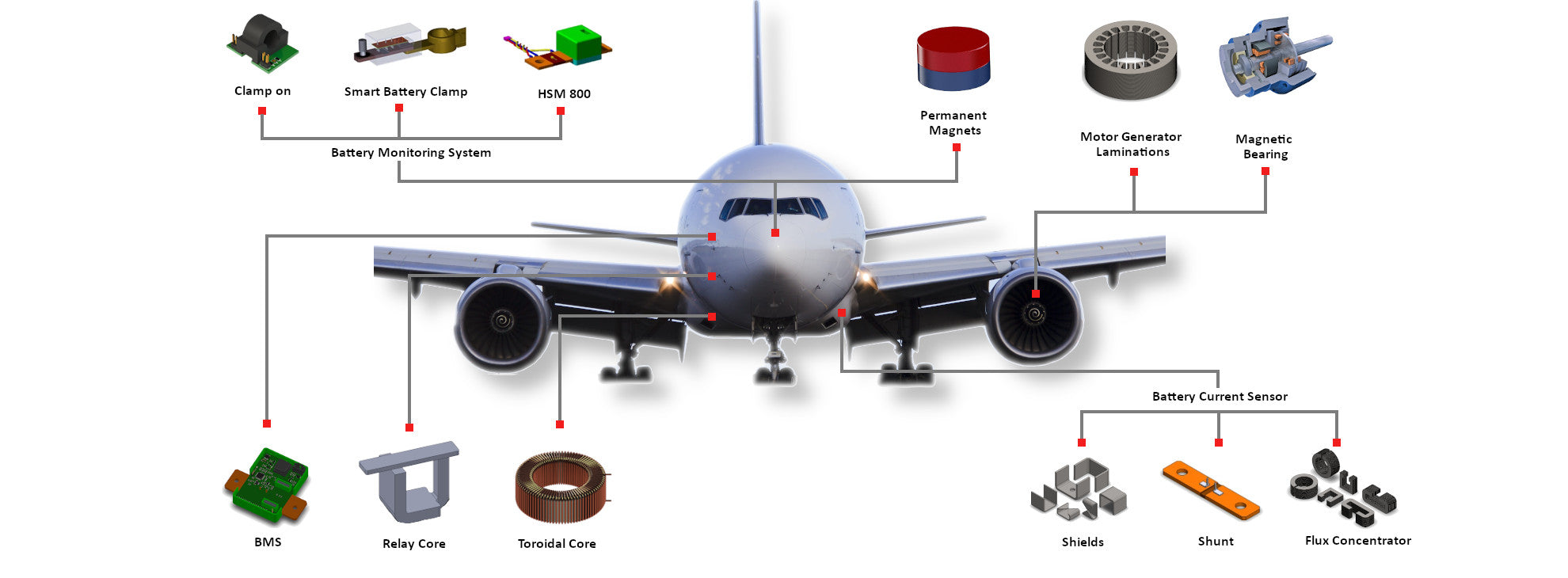

Components and Assemblies for Aerospace:

About:Our AS9100D certified QMS at “Hiperm Division” is into the supplies of various critical and non critical components used in the Aviation, Space and Defense industry. Besides manufacturing equipment such as High and Low speed Power Presses, grinding and finishing machines, Hiperm houses 20 Dry Hydrogen Heat Treatment furnaces. These furnaces are mapped according to AMS 2750 E pyrometry standards and are rated as Class 3. To ensure the functionality of the components and modules being supplied we have installed Quality measurement equipment such as Koerzimat, Ferrites India Loop Tracer. With the help of our technical experts we have also made Special Purpose Measurement Setups. These setups are qualified by our end customers as well.

We are in to manufacturing of soft magnetic components that includes - Stator and Rotor Lamination's for Motors,Axial wound cores for high RPM motors, Shields for very high attenuation for high and low field levels, RF Shields, Sub Assemblies for Sensors and Solenoids, Toroidal cores for Current Transformers and Components for Fuel Management Systems, Current sensing modules for various needs. We are proud suppliers to ISRO, SAC, OFB and many other Aerospace industries in India.