Product Description

Magnetic Filters are used for filtration of iron particles from products in liquid/slurry form. They are essentially used in chemical, food, pharma and oil industries. They are also frequently used in hydraulic circuits in cooling systems. The Filter Magnets are made up of either Ceramic or High-Intensity Rare Earth Magnets. Magnetic filter also called as pressure filter. Pml is magnetic filter manufacturers in india.

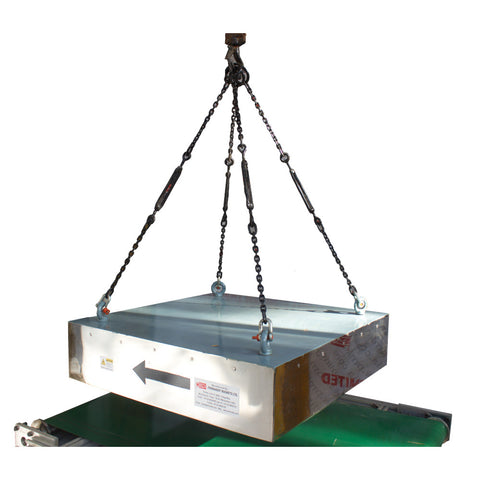

Application photos of Magnetic filter

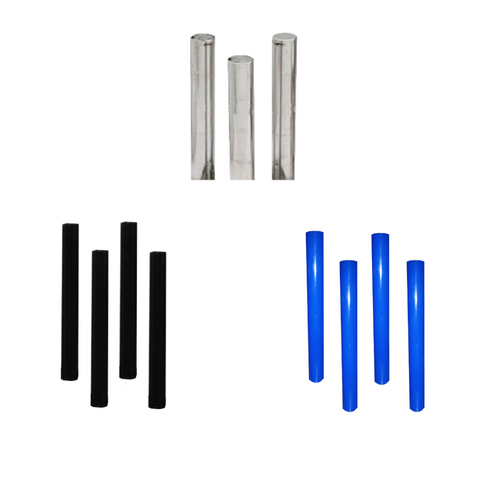

Magnetic Filter with PTFE coating

Magnetic Filter with ETFE coating anti-static food grade

Applications:

- Liquid Pharma products

- Liquid Chemicals

- Liquid Food products

- Lubricants

- Coolants

- Hydraulic oils

- Slurries

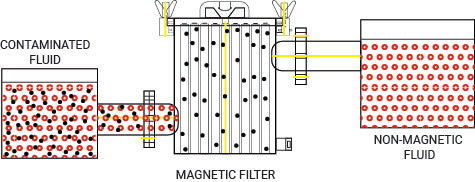

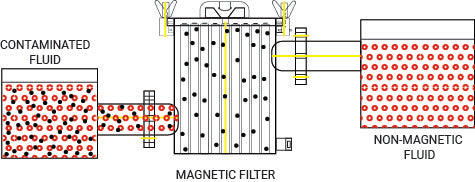

How does it work?

Magnetic filters are installed at a suitable location along the passage of fluid. The flowing liquid is made to travel around the magnetic field of high-intensity filter magnets where fine ferrous particles get arrested in a magnetic trap.

These arrested fine iron particles can be removed manually after removing the top lid of the filter. The drain plug is provided at the bottom face for periodical cleaning of the filter system.

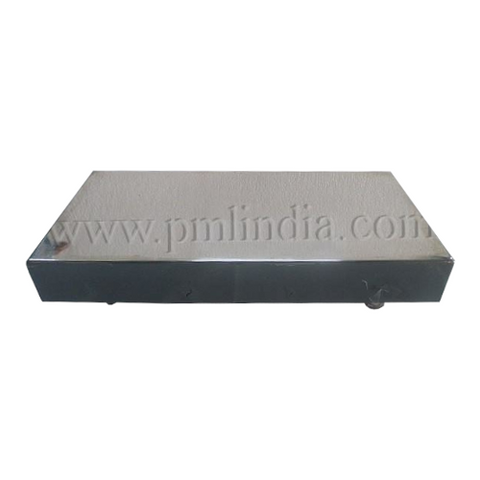

Construction:

The unit comprises a vessel, magnetic lid assembly and fasteners to secure the unit together. Magnetic system is made up of either Ceramic or High-intensity Rare Earth magnets. The Magnet unit is enclosed in stainless steel housing making it suitable for use in Chemical, Paper & Ceramic Industry. The Magnetic Filter is easily removable from the stainless steel enclosure by loosening a few quick-release fasteners.

Types

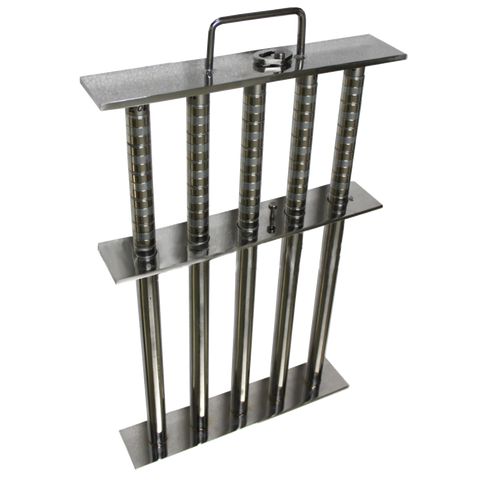

Manually Cleaned - (NdFeB Magnet – 11000 gauss)

These Magnetic filters are made up of Stainless Steel 304 / 316 shell with inlet and outlet flange connections and a drain plug. The filters are made up of high-intensity permanent magnets (Ndfeb) made in the form of elements. These magnetic elements are fixed on the top lid and are arranged in a circular format so that the liquid is exposed to the maximum area of elements. Once the fluid is passed through the filter, iron contamination gets arrested on the elements. This is removed manually after removing the top lid of the filter.

Self-cleaned - (NdFeB Magnet – 6500 gauss)

The self-cleaning filters consist of sleeves provided over the elements. The iron particles get trapped over the sleeve when the fluid is passed through the filter. When the elements are removed along with the top lid from the sleeves, the iron particles get dropped from the sleeve on the bottom of the filter this is removed through the drain plug by injecting pressurized water.

Standard PML Magnetic Filters:

| STANDARD PERMANENT MAGNETIC FILTER | ||||||

|---|---|---|---|---|---|---|

| Model No. | A (mm) | B (mm) | C (mm) | D (inch) | No. of Magnetic Elements | Recommended For Flow Rates* Liters/ per min |

| F001 / FH001 | 200 | 150 | 300 | 1" | 5 | 200 |

| F002 / FH002 | 250 | 200 | 350 | 2" | 5 | 500 |

| F003 / FH003 | 250 | 200 | 350 | 2" | 7 | 500 |

| F004 / FH004 | 300 | 300 | 500 | 3" | 9 | 1200 |

| F005 / FH005 | 450 | 300 | 500 | 3" | 12 | 2000 |

Note:

- The magnetic elements used in the filter have a gauss value of 11,000 gauss

- Standard ASA 150 flanges of 1”, 2”, 3” are used, however, on customers request, flanges of required sizes can be used

- Easy cleaning magnetic filters are available as an option

- High-intensity Filter with 9,000 guass value and maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).

PML also makes custom-designed Magnetic Filters to precisely fit customer’s applications. Information required is the following:

- Type of fluid

- Flow rate

- Size and concentration of contamination.

- Inlet and outlet flange connection

- The required volume of the fluid to be processed

Super High Intensity Magnetic Filter : 12,000 ± 500 Gauss Permissible Max. Operating Temp. 80˚C

| Model No. | A (mm) Height | B (mm) Dia | C (mm) | D (inch) PIPE DIA | No. of Magnetic Elements | Recommended For Flow Rates* Liters/ per min |

|---|---|---|---|---|---|---|

| SF001 | 200 | 150 | 300 | 1" | 5 | 200 |

| SF002 | 250 | 200 | 350 | 2" | 5 | 500 |

| SF003 | 250 | 200 | 350 | 2" | 7 | 500 |

| SF004 | 300 | 300 | 500 | 3" | 9 | 1200 |

| SF005 | 450 | 300 | 500 | 3" | 12 | 2000 |

Magnetic Filter Systems have the following features:

- The magnetic filters can be installed easily in the fluid flow line

- They give complete magnetic protection by attracting iron particles as fine as 10 microns into the magnetic trap

- The magnets are installed in polished condition for the higher life of the rods and ease of cleaning

- For different flow rates, different sizes of magnetic filters are available

- High-Intensity Rear Earth Magnets or Low-Intensity St. Ferrite Magnets are used depending upon the user's requirement

- Normally these filters are designed to take up pressures 5kg/sq cm. They can be designed to withstand higher pressure

- Maximum operating temperature 80ᵒC. They can be designed to work at temperatures as high as 200°C

Why PML Magnetic Filters?

- 45 years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Filters are available in 11,000 Gauss for operating temperature up to 120°C and 9000 Gauss at an operating temperature of 250°C

- Super high-intensity magnetic rod also available with guass value 12,000 for maximum operating temperature up to 80ᵒC.

- Customized design

- Magnetic Filters are hydraulically tested to check leakage at welding joints and sealing points.

- PML offers comprehensive Magnetic Filtration Systems using 2/3 Magnetic filters in series to ensure output contamination to a minimum PPM level.

- Services such as magnetic calibration/Audit are available

Videos of Magnetic Filter

FAQ for Magnetic filter.

- 1) Can magnetic filter be used for powder or dry products.

- Ans - No. Magnetic filter is specially designed for liquid / fluid products to separate iron particles from it.

- 2) Can magnetic filter separate desolved iron particles in liquid/fluid.

- Ans - No. Magnetic filter can separate only suspended iron particles present in liquid / fluid.

- 3) How to clean the traped iron particles.

- Ans - Presently there is no auto cleaning facility available. To clean the magnetic rods remove the top lead from the housing & wipe out the iron from the magnetic rods with the help of clean cloth.

- 4) Can filter housing be made of MS.

- Ans - No. MS attracts towards magnet, hence the magnetic circuit will get shorted with the ms housing which will reduce it's efficiency. Housing should be of S.S. only.

- 5) Is housing of Magnetic filter is also magnetic?

- Ans - Housing is not magnetic. The rods enclosed in the housing are magnetic which will catch iron particles.

- 6) Is electricity required to operate magnetic filter?

- Ans - Magnetic filter consists permanent magnets therefore it does not require power supply.

- 7) Can we use magnetic filter for highly corrosive / acidic liquid?

- Ans - Yes. We will provide HALAR , ETFE, FEP coatings for such applications.

- 8) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 9) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 10) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 11) Can we change Magnetic Rod of the Magnetic Filter?

- Ans - Magnetic Rods cannot be removed since they are welded with top lid of filter.

Our Valuable Customers for Magnetic filter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|