Product Description:

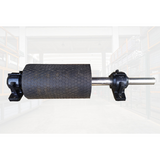

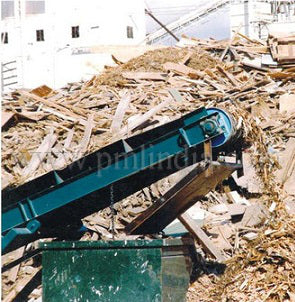

Permanent magnetic pulleys are ideal magnetic products used as head pulleys in belt conveyors. These pulleys offer superior removal of ferrous contamination like nails, spikes, nuts, bolts, cans, and wire from material conveyor with maintenance-free operation. Whatever your application is, a magnet is a low-cost way to remove that unwanted ferrous metal from your waste stream. They require very little maintenance and can last for years with proper care. PML is one of the Magnetic Pulley Manufacturer in India.

Applications:

- Waste stream

- Feed & Grain

- Mining

- Recycling Applications

- Cement

- Coal Handling Plant

- Salt processing industries

- Glass

- Paper

- Refractory

- Minerals (e.g. Bauxite)

Magnetic Pulley Installed at TATA STEEL KALINGANAGAR PLANT, Orissa

- Dia Meter 800mm X 2250 effective length

- High-Intensity Magnetic Pulley

- 4500±500 Gauss on Magnet Surface

How Does it work?

The magnetic field of the pulley attracts the ferrous fines which are held to the belt until it reaches the underside. The separated ferrous materials pass out of the magnetic field and are collected separately into a chute or bin. The cleaned material is discharged normally over the pulley in a vertical drop.

Magnetic Pulleys have following features:

- The magnetic pulleys can be installed easily at conveyor discharge

- They give complete magnetic protection over the entire face of the pulley for removing ferrous contaminants

- For different conveyors the magnetic pulleys of different sizes are available

- The pulleys either use ceramic magnets or powerful rare earth magnets

General Specification:

- Flux density: 4500 ± 200 gauss

- Attraction Distance: Up to 300mm / 12inches

- Maximum operating temperature 80ᵒC

- In all pulleys, best grade St. Ferrite/Rear Earth magnets are used for construction. The outer face and the endplates of the magnetic pulley are made out of stainless steel

- The magnetic pulley removes contaminants like nuts, bolts, wire, tools, etc.

- It protects equipment and product from the hazards of tramp iron

Types:

- High Intensity – (NdFeb Magnet – 4500 Gauss)

- Low Intensity - ( Ferrite Magnet - 1200 Gauss)

High intensity Magnetic pulley Permissible Max. Operating Temp. 80˚C

(Peak flux density value 5,000 ± 500 Gauss, when measured on Magnetic Surface)

| High intensity Magnetic pulley | |||||

|---|---|---|---|---|---|

| Model No. | Belt width | Pulley Size | Total Lg. | Shaft Dia. | Key Way Size |

| HMP 240 | 350 | Ø200 x 400LG. | 750 | Ø35 | 10W x 8 THK. |

| HMP 245 | 400 | Ø200 x 450LG. | 800 | Ø35 | 10W x 8 THK. |

| HMP 250 | 450 | Ø200 x 500LG. | 850 | Ø35 | 10W x 8 THK. |

| HMP 255 | 500 | Ø200 x 550LG. | 900 | Ø35 | 10W x 8 THK. |

| HMP 260 | 550 | Ø200 x 600LG. | 950 | Ø35 | 10W x 8 THK. |

| HMP 265 | 600 | Ø200 x 650LG. | 1000 | Ø35 | 10W x 8 THK. |

| HMP 270 | 650 | Ø200 x 700LG. | 1050 | Ø35 | 10W x 8 THK. |

| HMP 275 | 700 | Ø200 x 750LG. | 1100 | Ø35 | 10W x 8 THK. |

| HMP 280 | 750 | Ø200 x 800LG. | 1150 | Ø35 | 10W x 8 THK. |

| HMP 285 | 800 | Ø200 x 850LG. | 1200 | Ø35 | 10W x 8 THK. |

| HMP 290 | 850 | Ø200 x 900LG. | 1250 | Ø35 | 10W x 8 THK. |

| HMP 295 | 900 | Ø200 x 950LG. | 1300 | Ø35 | 10W x 8 THK. |

| HMP 2100 | 950 | Ø200 x 1000LG. | 1350 | Ø35 | 10W x 8 THK. |

| HMP 340 | 350 | Ø300 x 400LG. | 750 | Ø45 | 14W x 9 THK. |

| HMP 345 | 400 | Ø300 x 450LG. | 800 | Ø45 | 14W x 9 THK. |

| HMP 350 | 450 | Ø300 x 500LG. | 850 | Ø45 | 14W x 9 THK. |

| HMP 355 | 500 | Ø300 x 550LG. | 900 | Ø45 | 14W x 9 THK. |

| HMP 360 | 550 | Ø300 x 600LG. | 950 | Ø45 | 14W x 9 THK. |

| HMP 365 | 600 | Ø300 x 650LG. | 1000 | Ø45 | 14W x 9 THK. |

| HMP 370 | 650 | Ø300 x 700LG. | 1050 | Ø45 | 14W x 9 THK. |

| HMP 375 | 700 | Ø300 x 750LG. | 1100 | Ø45 | 14W x 9 THK. |

| HMP 380 | 750 | Ø300 x 800LG. | 1150 | Ø45 | 14W x 9 THK. |

| HMP 385 | 800 | Ø300 x 850LG. | 1200 | Ø45 | 14W x 9 THK. |

| HMP 390 | 850 | Ø300 x 900LG. | 1250 | Ø45 | 14W x 9 THK. |

| HMP 395 | 900 | Ø300 x 950LG. | 1300 | Ø45 | 14W x 9 THK. |

| HMP 3100 | 950 | Ø300 x 1000LG. | 1350 | Ø45 | 14W x 9 THK. |

| HMP 440 | 350 | Ø400 x 400LG. | 750 | Ø55 | 16W x 10 THK. |

| HMP 445 | 400 | Ø400 x 450LG. | 800 | Ø55 | 16W x 10 THK. |

| HMP 450 | 450 | Ø400 x 500LG. | 850 | Ø55 | 16W x 10 THK. |

| HMP 455 | 500 | Ø400 x 550LG. | 900 | Ø55 | 16W x 10 THK. |

| HMP 460 | 550 | Ø400 x 600LG. | 950 | Ø55 | 16W x 10 THK. |

| HMP 465 | 600 | Ø400 x 650LG. | 1000 | Ø55 | 16W x 10 THK. |

| HMP 470 | 650 | Ø400 x 700LG. | 1050 | Ø55 | 16W x 10 THK. |

| HMP 475 | 700 | Ø400 x 750LG. | 1100 | Ø55 | 16W x 10 THK. |

| HMP 480 | 750 | Ø400 x 800LG. | 1150 | Ø55 | 16W x 10 THK. |

| HMP 485 | 800 | Ø400 x 850LG. | 1200 | Ø55 | 16W x 10 THK. |

| HMP 485 | 800 | Ø400 x 850LG. | 1200 | Ø55 | 16W x 10 THK. |

| HMP 490 | 850 | Ø400 x 900LG. | 1250 | Ø55 | 16W x 10 THK. |

| HMP 495 | 900 | Ø400 x 950LG. | 1300 | Ø55 | 16W x 10 THK. |

| HMP 4100 | 950 | Ø400 x 1000LG. | 1350 | Ø55 | 16W x 10 THK. |

| HMP 540 | 350 | Ø500 x 400LG. | 750 | Ø65 | 18W x 11 THK. |

| HMP 545 | 400 | Ø500 x 450LG. | 800 | Ø65 | 18W x 11 THK. |

| HMP 550 | 450 | Ø500 x 500LG. | 850 | Ø65 | 18W x 11 THK. |

| HMP 555 | 500 | Ø500 x 550LG. | 900 | Ø65 | 18W x 11 THK. |

| HMP 560 | 550 | Ø500 x 600LG. | 950 | Ø65 | 18W x 11 THK. |

| HMP 565 | 600 | Ø500 x 650LG. | 1000 | Ø65 | 18W x 11 THK. |

| HMP 570 | 650 | Ø500 x 700LG. | 1050 | Ø65 | 18W x 11 THK. |

| HMP 575 | 700 | Ø500 x 750LG. | 1100 | Ø65 | 18W x 11 THK. |

| HMP 580 | 750 | Ø500 x 800LG. | 1150 | Ø65 | 18W x 11 THK. |

| HMP 585 | 800 | Ø500 x 850LG. | 1200 | Ø65 | 18W x 11 THK. |

| HMP 590 | 850 | Ø500 x 900LG. | 1250 | Ø65 | 18W x 11 THK. |

| HMP 595 | 900 | Ø500 x 950LG. | 1300 | Ø65 | 18W x 11 THK. |

| HMP 5100 | 950 | Ø500 x 1000LG. | 1350 | Ø65 | 18W x 11 THK. |

| HMP 640 | 350 | Ø600 x 400LG. | 750 | Ø75 | 20W x 11 THK. |

| HMP 645 | 400 | Ø600 x 450LG. | 800 | Ø75 | 20W x 11 THK. |

| HMP 650 | 450 | Ø600 x 500LG. | 850 | Ø75 | 20W x 11 THK. |

| HMP 655 | 500 | Ø600 x 550LG. | 900 | Ø75 | 20W x 11 THK. |

| HMP 660 | 550 | Ø600 x 600LG. | 950 | Ø75 | 20W x 11 THK. |

| HMP 665 | 600 | Ø600 x 650LG. | 1000 | Ø75 | 20W x 11 THK. |

| HMP 670 | 650 | Ø600 x 700LG. | 1050 | Ø75 | 20W x 11 THK. |

| HMP 675 | 700 | Ø600 x 750LG. | 1100 | Ø75 | 20W x 11 THK. |

| HMP 680 | 750 | Ø600 x 800LG. | 1150 | Ø75 | 20W x 11 THK. |

| HMP 685 | 800 | Ø600 x 850LG. | 1200 | Ø75 | 20W x 11 THK. |

| HMP 690 | 850 | Ø600 x 900LG. | 1250 | Ø75 | 20W x 11 THK. |

| HMP 695 | 900 | Ø600 x 950LG. | 1300 | Ø75 | 20W x 11 THK. |

| HMP 6100 | 950 | Ø600 x 1000LG. | 1350 | Ø75 | 20W x 11 THK. |

Customized Pulley Designs:

PML also makes custom-designed Magnetic Pulleys to precisely fit customer’s applications. The following information is required:

- Type of material

- Conveyor belt width

- Belt Speed

- Size and concentration of the contamination

- Burden depth

Construction

The magnetic pulley is made up of magnets placed inside a Stainless Steel 304/316 drum shell on a shaft. All shafts are made up of steel and are amply supported to handle the required load. Shafts are carefully machined from oversize stock to required finished dimensions. The magnets are enclosed totally inside the stainless steel drum. These are installed as a head pulley in belt conveyors. The self-cleaning magnetic pulleys are equally effective in the separation of both large and fine particles from non-ferrous material.

Installation

Installation is often very simple. Four bolts on a set of pillow block bearings normally hold the pulley in place. Loosen the conveyor belt, remove the old pulley and install the magnetized pulley. This type of installation does not require electricity.

Buying Tips:

Buyer before going for magnetic pulley must keep in mind the following considerations:

- The width of the pulley must match with the width of your equipment

- The diameter of the pulley and shaft must match the diameter of the equipment

- The pulley selected must fit into your conveyor system

Why PML Magnetic Pulley?

- 45 years of experience in design and development of Permanent Magnets and Magnetic Systems

- Easy to clean and no maintenance cost and preventing expensive shutdown and delays for equipment down the process line

- No power cost

- Installation of these Pulleys improves product quality thereby enhances product value

- Services such as magnetic calibration/Audit are available

- PML also makes customized design pulleys

Customer Reviews

FAQ for Magnetic Pulley

- 1) Can we get 10000 Gauss on the surface of magnetic pulley?

- Ans - No. Presently PML supplying Magetic pulley in 2 variations with 1200 Gauss & 4500 Gauss only.

- 2) Where to install magnetic pulley?

- Ans - Magnetic pulley shoule be used in belt coneyor. Customer can replace the exisiting Non-Magnetic pulley.

- 3) Does magnetic pulley comes with rubber lagging?

- Ans - If customer requires then rubbet lagging can be provided.

- 4) What is the range of magnetic field of pulley?

- Ans - Depending on it's size the magnetic range varies between 2 to 6 inches.

- 5) Does it require power supply for working?

- Ans - No. It is made up with permanent magnets.

- 6) How should i select the magnet size?

- Ans - Please select PML standard model as per size of the conveyor belt & system working at your end.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 9) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 10) Is this magnetic pulley efficient to remove 100% iron contamination from the material flowing over the conveyor belt?

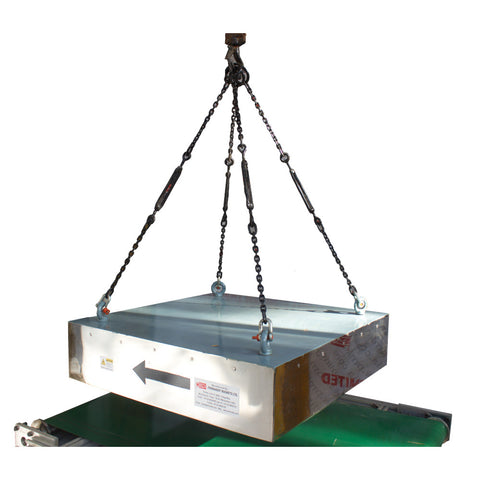

- Ans - It is advisable to use the suspended magnet & magnetic pulley in combination for effective to the removal of tramp iron.

Our Valuable Customers for Magnetic Pulley

|

|

|

|

|

|

|