Concept and Application

Safety devices are typically used to safeguard any machine, equipment and human life from electric shocks.Relays are the heart of any safety system.

Relays are basically protection or switching devices that isolates a system when the electrical current exceeds a limit. Thereby protecting the system from getting damage. This system can be an equipment or human body.All the relays respond to one or more electrical quantities like voltage or current.

There are various types of relays.

- Electromagnetic Relay

- Solid State Relay

- Hybrid Relay

- Thermal Relay

- Reed Relay, etc.

How does Relay work:

These Relays generally consists of Coil, Contact, Soft magnetic components, Permanent magnet (may or may not be present) Spring (may or may not be present)

When a relatively low current (secondary) is passed through the coil, the magnetic field attracts the contacts and the primary circuit is Opened. The current passed through the coil is a result of increase in primary current over set limit. In case of GFCI (Ground Fault Circuit Interrupter), this secondary current is due to difference in leakage of current in primary current (may be due to electrical shock). Thus saving the primary circuit (Equipment and Human life) from getting damaged.

Since, high permeability is required for relay to actuate precisely, these parts are generally made in 48% NiFe The contacts and soft magnetic components need to have very good surface finish and excellent magnetic properties.

PML provides these parts with Surface Finish:

- Roughness value(Ra) = 0.02 microns max.

- Flatness = 1 light band max.

Magnetic properties:

- For 48% Ni:Fe : AC Permeability at 5 mOe = 12000

- For 80% Ni:Fe : AC Permeability at 40 gauss = 85000

Because of such stringent surface requirements, there parts are to be tested in a very clean atmosphere. PML checks the parts in Class 100 clean environment.

What we can offer:

- Relays for Human safety

- GFCI (Ground Fault Circuit Interrupter)

- Auxiliary Relay for Machine safety

- CBCT (Circuit Breaker Current Transformer)

- Relays for Gas meters

FAQ for Relays

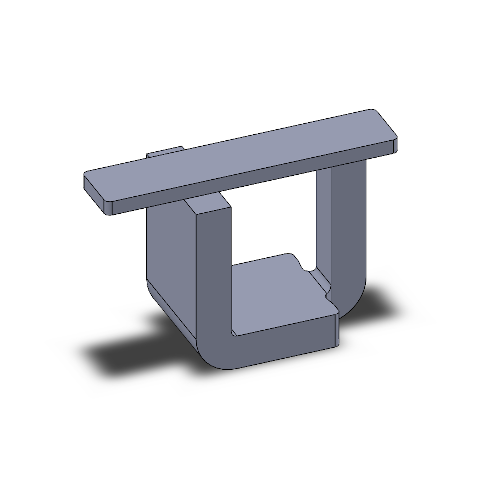

- Ans: A relay is an Electro-Mechanical switch that changes a low release current into mechanical movement. A polarized relay consists of a soft-magnetic circuit formed by an Armature and a Yoke.

- Ans: Relay parts are made in 80% NiFe or 48% NiFe material. These parts require very high permeability and the contact area needs to have very high surface finish, flatness and cleanliness. These parts are used in Earth Circuit Leakage Breakers (ELCB) or Residual Current Devices (RCDs) for Human Safety

- Ans: Auxiliary relays are used for machine safety. Auxiliary relay assists a protective relay in switch-gear for a number of operations. Protective Relay performs the task of measurement and under required conditions, it closes its contacts. Protective relay is relieved of all duties such as tripping, Time lag, breaking of trip circuit current, giving alarm, showing flags,etc. These duties are performed by Auxiliary Relays.Each of these duties are performed by an auxiliary relay.Seal-in Relay, Alarm Relay,Time lag Relay are some of the auxiliary relays. Contacts of Protective relay are delicate. Seal-in Relay is an auxiliary relay that protects the contacts of Protective relay. Alarm Relay is an auxiliary relay that gives trip alarm(Indication) both in audible and visual form. Time lag relays are auxiliary relays that operate after a preset time lag. They are used in control and alarm circuits to allow time for the required sequence of operation to take place. There are various applications of auxiliary relays. These parts are made of 48% Ni:Fe.PML provides these parts with high magnetic properties and critical dimensions maintained for proper working of the auxiliary relay.