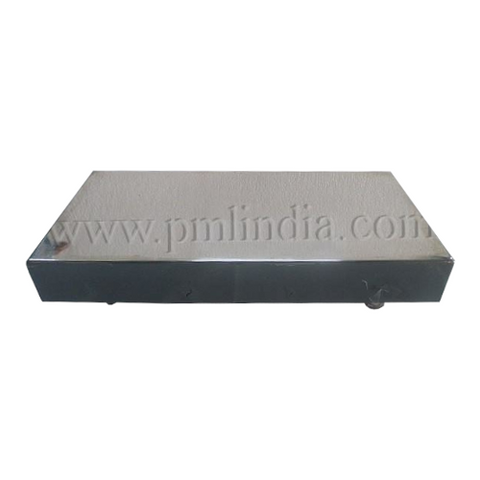

Plate Type Magnetic Chute

Available

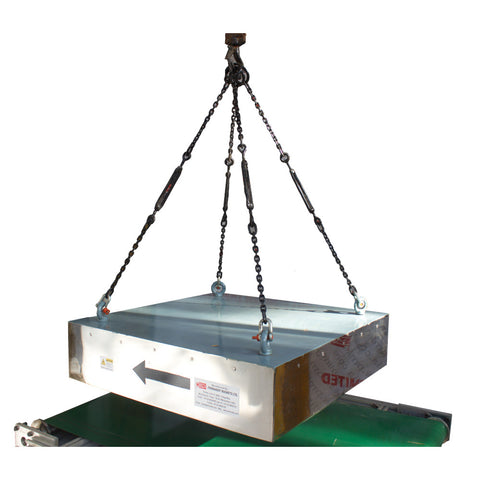

Plate Type Magnetic Chutes with plates are for trapping ferrous particles mixed with dry, granular or powdered materials. They are generally used where flowing material characteristics are sticky and non-free-flowing.These systems are easy to clean and maintain.

Industries Using Magnetic Chutes:

- Plastics

- Food

- Spices

- Chemicals

- Dyes & Powder Pigments

- Pharmaceutical industry

Standard PML Magnet Chutes:

| High intensity Easy-Clean Plate housing Magnet Permissible Max. Operating Temp. 80˚ C | |||

|---|---|---|---|

| Model | Inlet & outlet Dia.(mm) | Total HT.(mm) | Attraction Distance |

| ECPHM 1 | 150 | 300 | 4” |

| ECPHM 2 | 200 | 300 | 4” |

| ECPHM 3 | 250 | 400 | 4” |

| ECPHM 4 | 300 | 400 | 4” |

| ECPHM 5 | 350 | 400 | 4” |

(Peak flux density value 4,000 ± 500 Gauss, when measured on separation frame)

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model | Flange O.D.(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.(mm) |

| ECPHM 1 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| ECPHM 2 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| ECPHM 3 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| ECPHM 4 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| ECPHM 5 | 533.4 | 28.6 | 12 | 476.2 | 6 |

Construction:

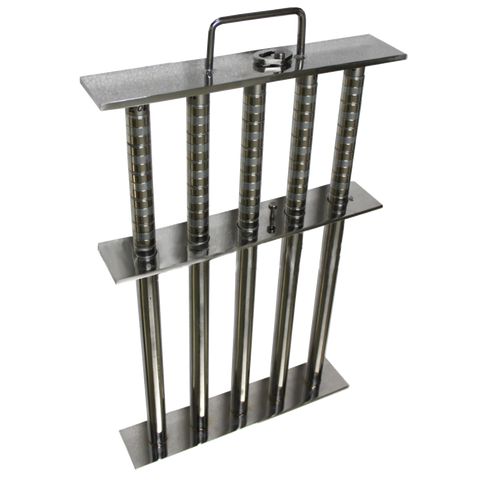

In a Plate type Magnetic Chute, the magnets are placed on the doors. The central Magnet is fitted on the hinged door and can be swung out for manual cleaning of arrested iron particles after the batch is over or at a decided frequency of cleaning. The chutes are generally placed vertically on the discharge ducts. However if required it can also be placed horizontally between the material flow lines.

Features:

Magnetic Chutes have following features:

- The Plate Type Magnetic Chutes can be installed easily in a flow line.

- The Flux density of Plate type magnetic chute (4,500) gauss is also available for 80ᵒC.

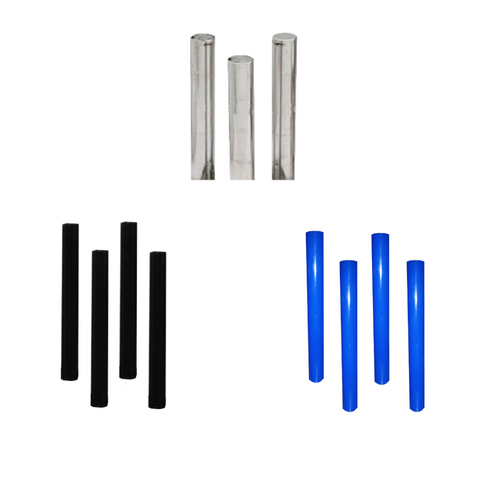

- High-intensity Bullet Rod Type Magnetic Chute with 9,000 gauss value and maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).For different flow rates, the magnetic chutes of different sizes are available.

- High-Intensity Rare Earth Magnets are used fitting best to the user’s requirement.

How does it work?

The plate type magnetic chute is placed in the flow path of the materials passing through the ducts, with the help of flanges. As the material flows through the chute, the iron contamination gets attracted to the magnetic surface and the non-magnetic material flows out of it without any disturbance.

Information required for the design of magnetic chutes:

- Size of the duct and the flange with which the chute has to be fixed

- Type of material and size of the particle

- Size and concentration of contamination

- Flow rate

Why PML Magnetic Chute?

- 60 years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Chutes are available with high intensity of 5000 Gauss

- Customized Design

- Services such as magnetic calibration/Audit are available

- Arrested iron particles can be easily removed manually

Some of PML’s valued customers:

- Kwality Feed

- Avanti Feeds

- National Capsules limited(NCL)

- NG Feeds

- Rajdeep Engineering Systems (Pune) Pvt Ltd.

- Huber Group

- Morava Group

- Rida Plastics