Product Description

PML Single Pole Suspended Magnets are placed above open conveyors to arrest ferrous objects and fines found in grains, feed stuffs, raw and processed products, dry chemicals, salt, ceramics, Clinkers in Cement Industry, Coal conveying in power plants and many other products.

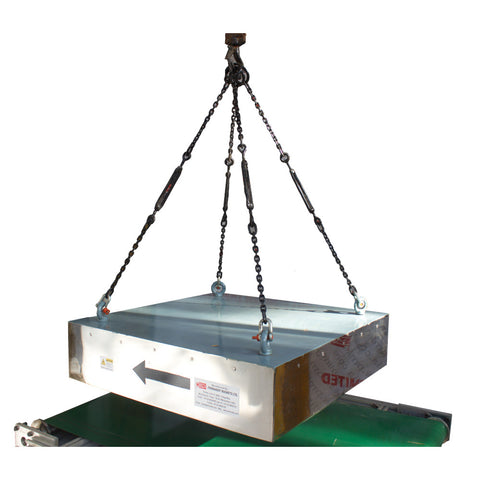

Application photos of Suspended Magnets

Price List for Standard Suspended Magnet:

| STANDARD PERMANENT SUSPENDED MAGNETS | |||

|---|---|---|---|

| Model No. | Dimension (W x L x H) mm |

For Conveyor Belt width (mm) |

Conveyor Belt Speed Mtr. / Sec. |

| SPSM-0050 | 500 x 500 x 154 | 500 | 1.0 |

| SPSM-0066 | 650 x 650 x 154 | 650 | 1.2 |

| SPSM-0068 | 650 x 800 x 154 |

650 | 1.6 |

| SPSM-0088 | 800 x 800 x 154 |

800 | 1.2 |

| SPSM-0810 | 800 x 1000 x 154 |

800 | 1.6 |

| SPSM-1010 | 1000 x 1000 x 154 |

1000 | 1.2 |

| SPSM-1012 | 1000 x 1200 x 154 |

1000 | 1.5 |

| SPSM-1212 | 1200 x 1200 x 154 |

1200 | 1.5 |

W= Width of Magnet. (This should be decided based on the width of the conveyor)

L= Length of Magnet (This should be decided based on the belt speed. Higher the speed, higher the length required.)

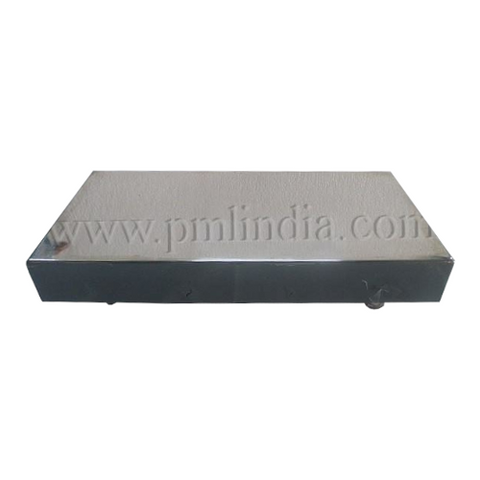

The material of Magnetic Surface: S.S. 304

General Specification:

- Flux density: 1400 ± 200 gauss.

- Attraction Distance: For M10 x 100 mm Length MS bolt Upto 250mm/10inches, If the free path is available.

- Height of Suspension magnet is 154mm

- The maximum operating temperature of 250 Degree C.

- In all suspension magnets, best grade St. Ferrite magnets are used for construction.

How does it work?

Suspended Magnet is placed over the conveying belts carrying the material. This system arrests Ferromagnetic materials from the distance of 300mm/12 inches from feed material which is transported through the production process.

Construction

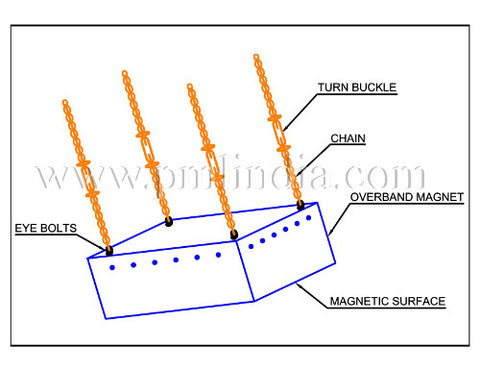

Suspended magnets are generally in big sizes depending upon the width and speed of the conveyor belt. They are provided with eye bolts, D shackles and sling chains with turnbuckles for adjustments while mounting.

| Suspended magnet - maximum tramp iron attraction distance chart | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sr. no. | Tramp Iron particle | Size in mm | Weight | Maximum Attraction distance in Inches | |||||||

| SPSM- 0050 |

SPSM- 0066 |

SPSM- 0068 |

SPSM- 0088 |

SPSM- 0810 |

SPSM- 1010 |

SPSM- 1012 |

SPSM- 1212 |

||||

| 1 | Paper clip | 30 mm | 0.6 gm | 10 | 12 | 12 | 13 | 13 | 13 | 14 | 14 |

| 2 | Stapler pin | 10 mm | 0.016 gm | 8 | 10 | 10 | 11 | 13 | 13 | 14 | 14 |

| 3 | Nail | DIA 2 X 45 L | 1.16 gm | 10 | 11 | 12 | 12 | 13 | 13 | 13 | 16 |

| 4 | Spanner | 8,9 | 20 gm | 7 | 11 | 11 | 11 | 12 | 12 | 15 | 15 |

| 5 | Spanner | 18,19 | 120 mg | 8 | 10 | 11 | 11 | 11 | 12 | 15 | 15 |

| 6 | Spanner | 20,24 | 200gm | 8 | 10 | 10 | 11 | 11 | 11 | 14 | 14 |

| 7 | Spanner | 33,37 | 500 gm | 8 | 10 | 10 | 11 | 11 | 11 | 14 | 14 |

| 8 | Bolt | M10 x 100 L. | 50 gm | 9 | 9 | 10 | 11 | 11 | 12 | 15 | 15 |

| 9 | Bolt | M20 x 100 L | 250 gm | 6 | 6 | 7 | 8 | 8 | 9 | 9 | 9 |

| 10 | Bolt | M16 x 60 | 100 gm | 7 | 7 | 9 | 9 | 10 | 10 | 10 | 11 |

| 11 | Nut | M16 | 10 gm | 6 | 6 | 7 | 7 | 7 | 8 | 9 | 9 |

| 12 | Nut | M8 | 5 gm | 4 | 4 | 5 | 6 | 6 | 6 | 7 | 8 |

| 13 | Washer | OD 25 X ID 10 X 2 THK | - | 5 | 5 | 8 | 11 | 11 | 11 | 11 | 12 |

| 14 | Washer | OD 17 X ID 9 X 1.5 THK | - | 4 | 4 | 8 | 8 | 9 | 9 | 9 | 10 |

| 15 | Round M.S.Piece | Dia 23 x 2 THK | - | 6 | 6 | 7 | 7 | 7 | 7 | 11 | 11 |

| 16 | Round M.S. Piece | Dia 30 x 1.5 THK | - | 6 | 8 | 8 | 9 | 9 | 9 | 9 | 10 |

| 17 | Std. weight | - | 500 gm | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 |

| 18 | Std. weight | - | 1 kg | 5 | 5 | 6 | 6 | 6 | 6 | 7 | 7 |

| 19 | Std. weight | - | 2 kg | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 |

| 20 | Std. weight | - | 5 kg | 6 | 6 | 7 | 7 | 7 | 7 | 8 | 8 |

| 21 | M.S.angle | 770 L X 80 W X 40 H | 1.5 kg | 9 | 10 | 12 | 12 | 13 | 14 | 15 | 17 |

| 22 | Channel | 700 L X 50 W X 50 H | 2.64 kg | 8 | 11 | 13 | 13 | 14 | 14 | 16 | 17 |

| 23 | Channel | 365 x 20 x 20 | - | 7 | 13 | 13 | 13 | 13 | 14 | 15 | 15 |

Note:

- The above attraction distances are taken at a point below the geometrical center point of the suspended magnet assembly.

- The above trial results are obtained when the free path is available for tramp iron particles.

- The above chart is given for reference. One may get a deviation of 1 to 2 inches in attraction distances depending on actual site conditions.

- The MOC of rollers & frames of the conveyor should be of nonmagnetic material (S.S.304), otherwise, all the magnetic flux will pass through the conveyor & it will reduce the efficiency of the magnet.

- It is advisable to use the suspended magnet & magnetic pulley in combination for effective to the removal of tramp iron.

Why PML Suspended Magnet?

- 45 years of experience in the design and development of Permanent Magnets and Magnetic Systems.

- Mounting chains are tested and certified for load-bearing capacity by a government-approved testing Authority.

- Customized Design

- Services such as magnetic calibration/Audit are available.

- Easy to clean and no maintenance cost and preventing expensive shutdown and delays for equipment down the process line.

- No power cost.

- Installation of these Suspended Magnets improves product quality thereby enhances product value.

- Services such as magnetic calibration/Audit are available.

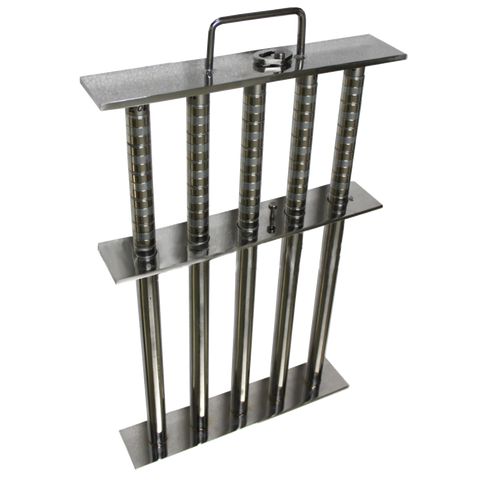

- PML also makes customized design and self-cleaning grills.

Some of PML’s Valued customers:

- Ambuja Cements Ltd.

- K. White Cements Ltd.

- Ultratech Cements Ltd.

- Sterlite Industries Ltd.

- RISHABH Stone Crushing Ltd.

- Grasim Industries Ltd.

- BLA Power Ltd.

- Mangalore Chemical & fertilizers Ltd.

- Goa Carbon Ltd.

- Trivent Earth Movers Pvt Ltd.

- Chettinad Cements Ltd.

- Shi Vishnu Cements Ltd.

- Gujrat Sidhi Cements Ltd.

- Metso Minerals Pvt Ltd.

- Kerala Chemicals & Proteins Ltd., Kochi

- Gujrat Fluorochemical Ltd., Bharuch

- Praweg Conveyors Thane

- AGI Glasspac Hyderabad

- Monara Engineering & Trading (P) Ltd., Sri Lanka

FAQ for Suspended Permanent Magnet

- 1) How much kg of iron it can lift & from what distance?

- Ans - The attarction height of the magnet depends upon the weight & shape of the tramp iron. Please refer the weight Vs attarction distance chart for different type of objects for each magnet model.

- 2) Is it require power supply for operation?

- Ans - No it made-up of permanent magnets hence do not require power supply.

- 3) Is there any demagnetisation facility available to remove trapped iron?

- Ans - No. The trapped iron have to remove manually only.

- 4) Is magnet comes with chain slings ?

- Ans - Yes we will provide 4 Nos of chain slings alongwith the magnet.

- 5) How should i select the magnet size?

- Ans - Please select PML standard model as per size of the conveyor belt at your end.

- 6) What type of iron contamination it can lift?

- Ans - Suspende magnet is used to separate tramp iron like bolts, broken spanners, angles, rod, nuts etc. Please refer the weight Vs attarction distance chart for different type of objects for each magnet model.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 9) Can we install suspended magnet at height more than 300 mm?

- Ans - No, Suspenended Magnet can work efficiently with operating height 300 mm (12 Inches).

- 10) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 11) Does it have any effect on human body?

- Ans - Magnet doesn't have any effect of human body. The persone who is using heart spacemaker should not go near the magnet as the magnetic field may affect on working of the spacemaker.

- 12) Is this magnet efficient to remove 100% iron contamination from the material flowing over the conveyor belt?

- Ans - It is advisable to use the suspended magnet & magnetic pulley in combination for effective to the removal of tramp iron.

Our Valuable Customers for Suspended Permanent Magnet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|