Introduction

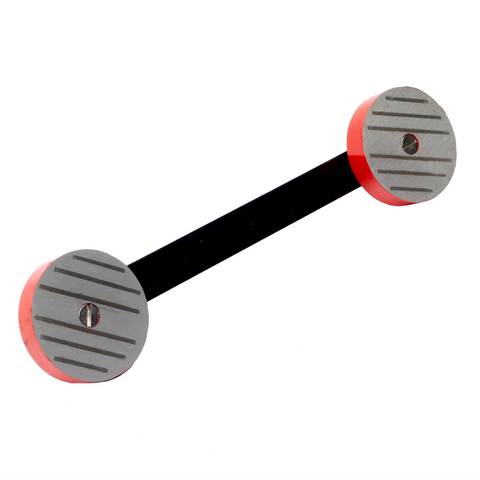

Precast magnet also known as a Formwork Magnet

With the rapid development of the prefabricated construction industry, magnetic fixed products such as shuttering magnets have been fully applied in the production of precast concrete components. The magnetic block is directly embedded in the formwork, so it is more convenient, more efficient and more stable than the magnetic box.

Through the adhesive force of the magnetic block, the formwork is in close contact with the template, so that the formed formwork system is fixed. The formwork system that needs to be formed is thus fixed. Since the steel formwork and the magnetic blocks are integrated, no positional movement occurs and the formwork system is not deformed. At the same time, the simple and quick operation of the magnets makes the whole work safer and more stable. With the matching pry bar, the formwork magnet can be picked up and the steel formwork can be easily removed from the template. Since the magnets are located inside the steel formwork groove, concrete residue or other dirt does not cause damage to the entire formwork system.

Product Description

Precast Concrete Magnet/ Shuttering Magnet is the new type building material widely used in construction site, High- Developments projects,etc, Railway Infrastructure projects etc. in precast concrete form-work system. There by increasing building stability, while reducing labor costs and cost savings.

The precast concrete Form-works are afforded the opportunity to properly cure and be closely monitored by plant employees. Using a precast concrete form-work offers many potential advantages over on-site casting. Precast concrete production performed on ground level, which helps with safety throughout a project.

There is greater control over material quality and workmanship in a precast plant compared to a construction site. The forms used in a precast plant can be reused hundreds to thousands of times before they have to be replaced, often making it cheaper than on-site casting when looking at the cost per unit of form-work.

General Specifications

The precast concrete formwork magnet consists of a steel formwork and embedded magnets.

Form-work Material and Treatment Process

Q235A Carbon Steel, Blackening Treatment

Q235A carbon steel is generally used, which has better magnetic flux than stainless steel and low cost. The anti-rust treatment of the iron shell is usually blackening. It is a common method of chemical surface treatment. The principle is to produce an oxide film on the metal surface to isolate the air and achieve the purpose of anti-rust.

Construction

The bolt lifting system mainly includes: spreader, anchor and rubber recess former.

The bolt lifting system is a safe, effective, quick-connect and disconnect system for handling and transporting precast concrete construction. Fast, safe and affordable. It is a non-welding system, all bolts are made of hot forged or cold forged steel, high quality, reusable. The safety load rating of the bolt hoisting system is 1 to 32T. Each element has a clearly labeled maximum safe workload, it can be used to hoist concrete prefabricated components and lift from a horizontal position to a vertical position without the help of a tilting table. For each batch, we wll conduct strict inspections including raw material quality inspection, semi-quality inspec- tion, product quality inspection, and inspection of possible tolerances and deviations. For each bolt spreader, we will test all according to the specified load safety factor.

Safety Introduction

- All lifting anchors must be installed in accordance with the safe use guidelines.

- The anchor is only suitable for temporary use and cannot be used for permanent fastening purposes.

- All technical data provided must be considered to ensure safe use.

- The anchor is designed for a minimum safety factor of 3.

- Lifting Anchors cannot be used repeatedly (repeated lifting during lifting and transport, not considered as repeated use)

- Conditions that cannot be used, such as incorrect installation, or damage to parts, corrosion

Advantages of Precast Concrete Magnet

- Easy to operate.

- Use with wood or steel form-works.

- Simple and exact positioning.

- Adhesive force ranging from 450 Kg to 2100 Kg.

- Avoid welding or bolting to the form-work table thus preserving surface finish.

- Same magnet can be used for various application.

- Integrated threaded holes to adapt form-work.

- Adapters to be custom made.

| PML Precast Concrete Magnets | ||||||

|---|---|---|---|---|---|---|

| MODEL-NO | Force | L | W | H | L1 | H1 |

| Unit | Kg | mm | mm | mm | mm | mm |

| PCM-600 | 600 | 186 | 70 | 60 | 136 | 96.5 |

| PCM-900 | 900 | 310 | 86 | 60 | 260 | 96.5 |

| PCM-1600 | 1600 | 310 | 120 | 60 | 260 | 96.5 |

| PCM-2100 | 2100 | 310 | 120 | 60 | 260 | 96.5 |

| PCM-2500 | 2500 | 310 | 120 | 60 | 260 | 96.5 |

NOTE

- The forces have been determined at room temperature on a plate in polished steel (Q235B) with a thickness of 10 mm (80mm/min).

- Maximum deviation of -10% compared to the specified value is possible in exceptional cases.

- Value is exceeded in general.

- Depending on the type of application (installation situation, temperatures, counter anchor, etc.) the forces can be influenced enormously.

- The indicated values are serving as an orientation.

Please get advice and help from our experts.

Why PML’s Precast Magnet?

- These Precast Magnets are ruggedly built

- High holding Capacity with respect to size & weight

- No maintenance and operational costs

- Very easy to use - Save time & energy

- Made with high energy rare earth magnets (NdFeB)

- Mechanical Switching by pulling a lever with a releasing tool

- Easily transportable

- Reliable