Description

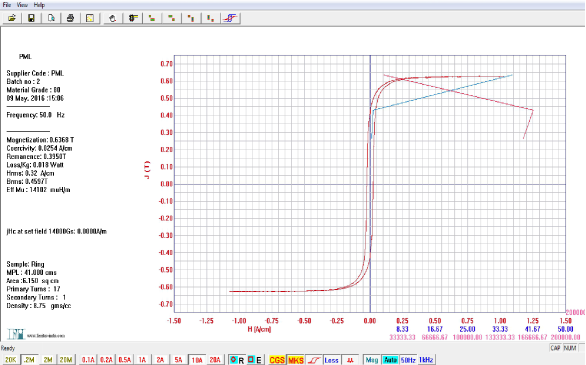

Permanent Magnets Ltd. (PML) supplies Cut cores in soft magnetic Nickel alloy material to industries requiring High accuracy flux Concentrator used in current sensing application. Depending on the application, customers can select suitable Nickel or Silicon Iron alloy. PML maintains close control of magnetic properties by properly heat treating in a controlled hydrogen atmosphere furnace, which permits the most economical and efficient design for transformers. PML manufactures Cut cores in Toroid and Rectangular shape. The cut cores are made robust by finishing them with varnish coating.