Product Description

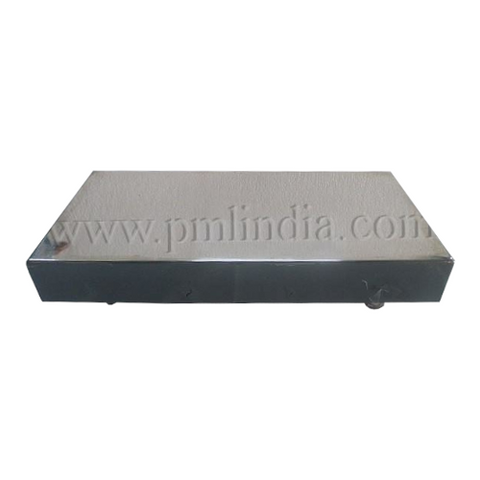

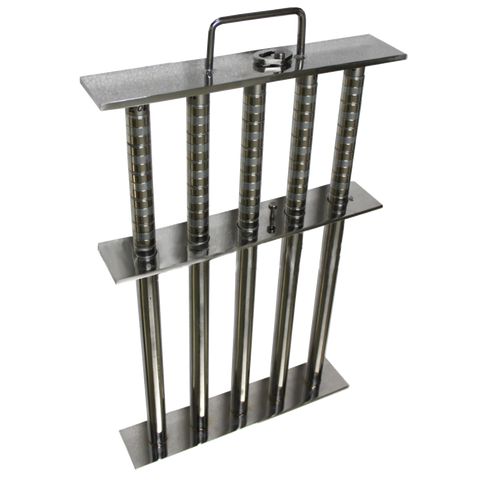

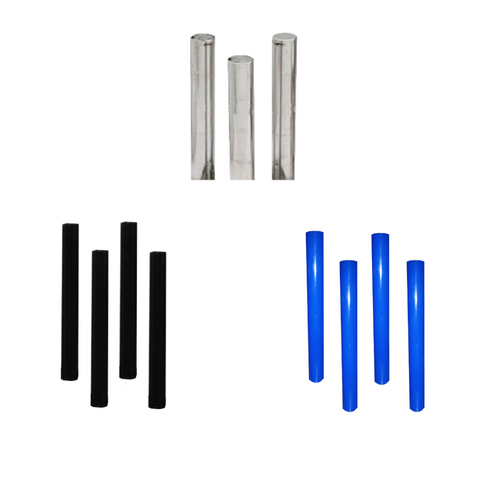

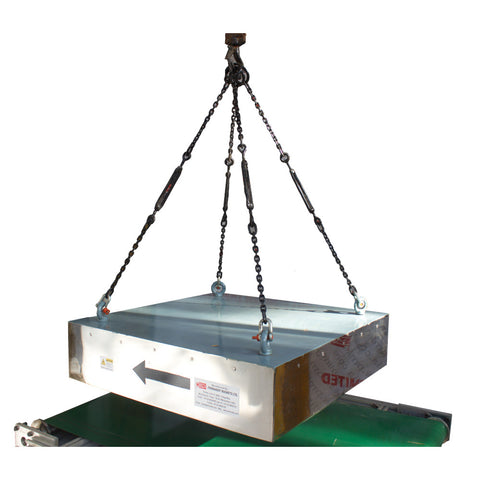

Self cleaning Drawer Type Permanent Magnetic grill are used for the separation of iron particles from dry, granular or free-flowing products/materials. Drawer Magnetic Grills are made by using stainless steel having (Round or square or rectangular) with magnetic rods mounted on the drawer.

The Drawer Type grills are made up of magnetic elements, which are fitted in a drawer and are moved in a housing. Magnetic Elements are made up of high-intensity rare earth magnets ( NdFeB ). All the components are made up of Stainless Steel 304/316 material. The overall construction of the magnetic grills can also be made as per the customer specification and sizes

The grills are efficiently utilized if contamination is within 1% to 1.5% by weight. For higher levels of contamination Drawer Grills or Multi Drawer Grills should be used.

High-Intensity Magnetic Grill having Gauss value of approximately 11,000 Gauss are employed at locations where the separation of contamination particles as small as 1 micron is required. These grills have been designed to attract super fine particles from the carrier material.

The Magnetic grill is supplied with the pneumatic cylinders, FRL Unit & Timer with Operating button for controlling the cleaning.

Cleaning Operation

- Start: After manually or electrically actuating the solenoid, the cylinders retract, pulling the magnetic tubes through the stripper assembly to deposit the collected tramp iron outside of the product flow area

- Finish: The cylinders return to the run position, pushing the magnetic tubes back into the housing (working position)

Schematic drawing for Single stage self cleaning grill

| SINGLE STAGE SELF CLEANING GRILL | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model No. | Inlet & outlet Dia.(mm) | Total HT.(mm) | No. Of Magnetic Elements | Flange O.D.(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.(mm) |

| SCG1 | 100 | 300 | 3 | 228.6 | 19 | 8 | 190.5 | 6 |

| SCG2 | 150 | 300 | 4 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| SCG3 | 200 | 300 | 5 | 342.9 | 22.2 | 8 | 298.4 | 6 |

| SCG4 | 250 | 300 | 5 | 406.4 | 25.4 | 12 | 361.9 | 6 |

| SCG5 | 300 | 300 | 6 | 482.6 | 25.4 | 12 | 431.8 | 6 |

| SCG6 | 350 | 300 | 7 | 533.4 | 28.6 | 12 | 476.2 | 6 |

| SCG7 | 400 | 300 | 8 | 596.9 | 28.6 | 16 | 539.7 | 6 |

Schematic drawing for Double stage self cleaning grill

| DOUBLE STAGE SELF CLEANING GRILL | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model No. | Inlet & outlet Dia.(mm) | Total HT.(mm) | No. Of Magnetic Elements | Flange O.D.(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.(mm) |

| DSCG1 | 100 | 400 | 5 |

228.6 | 19 | 8 | 190.5 | 6 |

| DSCG2 | 150 | 400 | 7 |

279.4 | 22.2 | 8 | 241.3 | 6 |

| DSCG3 | 200 | 400 | 9 |

342.9 | 22.2 | 8 | 298.4 | 6 |

| DSCG4 | 250 | 400 | 9 |

406.4 | 25.4 | 12 | 361.9 | 6 |

| DSCG5 | 300 | 400 | 11 |

482.6 | 25.4 | 12 | 431.8 | 6 |

| DSCG6 | 350 | 400 | 13 |

533.4 | 28.6 | 12 | 476.2 | 6 |

| DSCG7 | 400 | 400 | 15 |

596.9 | 28.6 | 16 | 539.7 | 6 |

Product Features:

- Self cleaning, air operated, for remote installations, frequent cleaning, or fully automated system

- Removable Collection tray

- Removes Micron size iron contamination

- Wear resistant tube treatment and special wiper seals for abrasive products

- Customized grill designs and magnetic grid designs available.

- FDA approved Food grade gasket material

- Finish and welding treatments available for food and sanitary grade applications

- Matching companion Flanges for easy installation.

- 316L stainless steel construction

- Custom housing designs for magnet in hopper or angled chute installations

- The air-actuated stripper seal assembly discharges collected tramp metal into a catch pan as the drawer opens.

- High-intensity Drawer Type Grill with Maximum operating temperature up to 350ᵒC also available with SMCO (Samarium Cobalt Magnet).

Why PML Magnetic Grill?

- 45+ years of experience in design and development of Permanent Magnets and Magnetic Systems

- Magnet Grills are also available with 12,000 Gauss for operating temperature up to 200°C

- Easy to clean and no maintenance cost and preventing expensive shutdown and delays for equipment down the process line

- No Labour cost

- Installation of these grills improves product quality thereby enhances product value and helps in meeting FDA and other government/customer regulations on iron contamination levels

- Services such as magnetic calibration/Audit are available

Some of PML’s valued customers:

- Amul dairy

- Govind Dairy

- NALCO

- Dinshaw

- Hindustan Unilever (All plants in India)

- Cipla Ltd (All plants in India)

- H & R Johnson (India) Ltd

- Lucid India Ltd, Jodhpur

- Tata Tea Ltd (All plants in India)

- Rossell tea

- Kanan Devan tea

- Pidilite Industries (Vapi)

- Hindustan Inks & resins Ltd (Vapi)

- Sudarshan Chemicals Ltd (Roha, Mahad, & Pune plants)

- Nepal Lever Ltd (Nepal)