Introduction

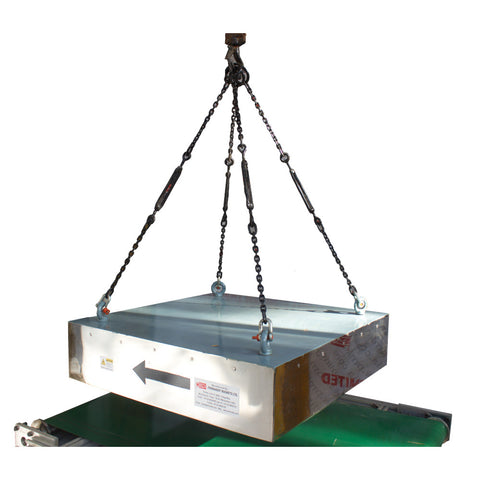

Hump Magnets are made for gravity free-fall applications in magnetic separation free flowing products such as feed, grain, wood ships, food stuffs, sand or plastic where the material flow rate is high & nature of material is lumsy.

It also can be used for granular & powder like material.

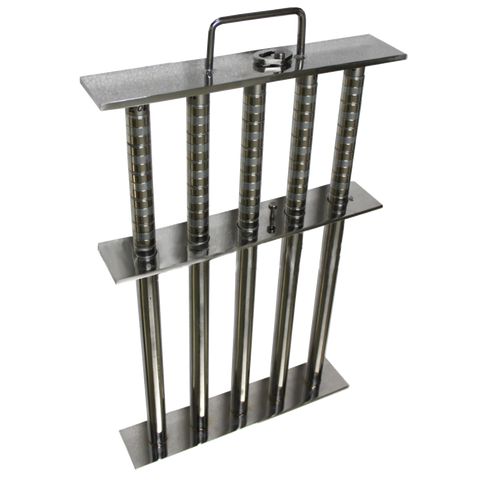

Magnetic Hump

Magnetic hump consists of two Magnetic plates mounted in an offset direction & are installed in vertical housing.

Housings handle gravity, moderate positive and negative pressures. The angled shape directs the product flow into the magnetic field & also prevents the bridging & built up of material.

The material falling strikes directly on the first magnet changes direction and falls over the second magnet, ensuring clean outflow material.

For below tables refer this drawing for Round & square type Magnetic Hump

High intensity Magnetic Hump - for 4,500 ± 500 Gauss

| ROUND SHAPE HIGH INTENSITY MAGNETIC HUMP (RHMH) - Permissible Max. Operating Temp. 80˚C | |||||

|---|---|---|---|---|---|

| Model | Inlet & outlet Dia.(mm) | Total Height(mm) | Total Attraction(inch) | Magnetic Plate Size(mm) | Magnetic Area(mm) |

| RHMH - 10 | 100 | 800 | 3” | 205 x 105 x 46 HT | 180 x 80 |

| RHMH - 15 | 150 | 800 | 4” | 255 x 155 x 46 HT | 230 x 130 |

| RHMH - 20 | 200 | 950 | 4” | 305 x 205 x 46 HT | 280 x 180 |

| RHMH - 25 | 250 | 1100 | 4” | 355 x 255 x 46 HT | 330 x 230 |

| RHMH - 30 | 300 | 1200 | 4” | 405 x 305 x 46 HT | 380 x 280 |

| Peak flux density value 4,500 ± 500 Gauss, when measured on Magnetic Plate | |||||

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model | Flange O.D.(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.(mm) |

| RHMH - 10 | 228.6 | 19 | 8 | 190.5 | 6 |

| RHMH - 15 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| RHMH - 20 | 342.9 | 22.2 | 8 | 298.4 | 8 |

| RHMH - 25 | 406.4 | 25.4 | 12 | 361.9 | 8 |

| RHMH - 30 | 482.6 | 25.4 | 12 | 431.8 | 8 |

High intensity Magnetic Hump - for 4,500 ± 500 Gauss

| SQUARE SHAPE HIGH INTENSITY MAGNETIC HUMP (SHMH) - Permissible Max. Operating Temp. 80˚C | |||||

|---|---|---|---|---|---|

| Model | Inlet & outlet Dia.(mm) | Total Height(mm) | Total Attraction(inch) | Magnetic Plate Size(mm) | Magnetic Area(mm) |

| SHMH - 10 | 100X100 | 800 | 3” | 205 x 105 x 46 HT | 180 x 80 |

| SHMH - 15 | 150X150 | 800 | 4” | 255 x 155 x 46 HT | 230 x 130 |

| SHMH - 20 | 200X200 | 950 | 4” | 305 x 205 x 46 HT | 280 x 180 |

| SHMH - 25 | 250X250 | 1100 | 4” | 355 x 255 x 46 HT | 330 x 230 |

| SHMH - 30 | 300X300 | 1200 | 4” | 405 x 305 x 46 HT | 380 x 280 |

| Peak flux density value 4,500 ± 500 Gauss, when measured on Magnetic Plate | |||||

Low intensity Magnetic Hump - for 1,500 ± 200 Gauss

| ROUND SHAPE LOW INTENSITY MAGNETIC HUMP (RLMH) - Permissible Max. Operating Temp. 250˚C | |||||

|---|---|---|---|---|---|

| Model | Inlet & outlet Dia.(mm) | Total Height(mm) | Total Attraction(inch) | Magnetic Plate Size(mm) | Magnetic Area(mm) |

| RLMH - 10 | 100 | 800 | 4” | 205 x 105 x 81 HT | 180 x 80 |

| RLMH - 15 | 150 | 800 | 5” | 255 x 155 x 81 HT | 230 x 130 |

| RLMH - 20 | 200 | 950 | 6” | 305 x 205 x 81 HT | 280 x 180 |

| RLMH - 25 | 250 | 1100 | 6” | 355 x 255 x 81 HT | 330 x 230 |

| RLMH - 30 | 300 | 1200 | 6” | 405 x 305 x 81 HT | 380 x 280 |

| Peak flux density value 1,500 ± 200 Gauss, when measured on Magnetic Plate | |||||

| Dimensions of Inlet & Outlet Connecting Flanges | |||||

|---|---|---|---|---|---|

| Model | Flange O.D.(mm) | Hole Dia.(mm) | No. Of Holes | Hole PCD(mm) | Flange THK.(mm) |

| RLMH - 10 | 228.6 | 19 | 8 | 190.5 | 6 |

| RLMH - 15 | 279.4 | 22.2 | 8 | 241.3 | 6 |

| RLMH - 20 | 342.9 | 22.2 | 8 | 298.4 | 8 |

| RLMH - 25 | 406.4 | 25.4 | 12 | 361.9 | 8 |

| RLMH - 30 | 482.6 | 25.4 | 12 | 431.8 | 8 |

Low intensity Magnetic Hump - for 1,500 ± 200 Gauss

| SQUARE SHAPE LOW INTENSITY MAGNETIC HUMP (SLMH) - Permissible Max. Operating Temp. 250˚C | |||||

|---|---|---|---|---|---|

| Model | Inlet & outlet Dia.(mm) | Total Height(mm) | Total Attraction(inch) | Magnetic Plate Size(mm) | Magnetic Area(mm) |

| SLMH - 10 | 100X100 | 800 | 4” | 205 x 105 x 81 HT | 180 x 80 |

| SLMH - 15 | 150X150 | 800 | 5” | 255 x 155 x 81 HT | 230 x 130 |

| SLMH - 20 | 200X200 | 950 | 6” | 305 x 205 x 81 HT | 280 x 180 |

| SLMH - 25 | 250X250 | 1100 | 6” | 355 x 255 x 81 HT | 330 x 230 |

| SLMH - 30 | 300X300 | 1200 | 6” | 405 x 305 x 81 HT | 380 x 280 |

| Peak flux density value 1,500 ± 200 Gauss, when measured on Magnetic Plate | |||||

Features

- The Z type design helps to break lumps & facilitate to trap embedded iron material from the product.

- SS 304 & SS 316Stainless steel construction.

- The High power magnetic plates are hinged type & can be easily cleaned periodically.

- Most preferable for high volume poor flowing or abrasive materials.

- Available in two variants i.e. High intensity with Flux density of 4500 +/-500 Gauss for & Low intensity i.e with Flux density of 1200+/-500 Gauss for attraction upto 4” distance.

- Maintenance Free

- No power supply required.

- Efficient cost-saving recovery of harmful tramp iron in free-flowing materials

Why PML Magnetic Hump?

- PML has been a Permanent Magnet Manufacturer for over 60 years and has great experience in design and development of Permanent Magnets and Magnetic Equipment.

- Customized Design.

- Services such as Magnetic calibration/Audit are available.

- PML's Magnetic Equipment are known to provide excellent Magnetic Separation of Material.

FAQ for Magnetic Hump

- 1) How to clean the magnet?

- Ans - The magnetic plates are provided with hinges to open it for cleaning. The catched iron on the magnetic plate can be remove by wiping the clothe manually.

- 2) How to install the magnetic hump?

- Ans - The ASA standard flanges are provided at inlet & outlet to install the hump into process line

- 3) In what direction magnetic hump should be installed?

- Ans - Vertical direction only.

- 4) Is it leak proof?

- Ans - Yes. Gaskets are provided at magnet opening to prevent material leakage.

- 5) What are the variations available?

- Ans - There are two types of Magnetic humps available. A) 4500 gauss Best for separation of Fine iron B) 1200 gauss Best for separation of tramp iron

- 6) Can we feed material manually?

- Ans - No, it is always recommended to use feeding system for regulated & even material feeding. This will help for better iron removal from material.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 9) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 10) How should i select the magnet size?

- Ans - Please select PML standard model as per material flow rate & type of iron contamination.