Product Description

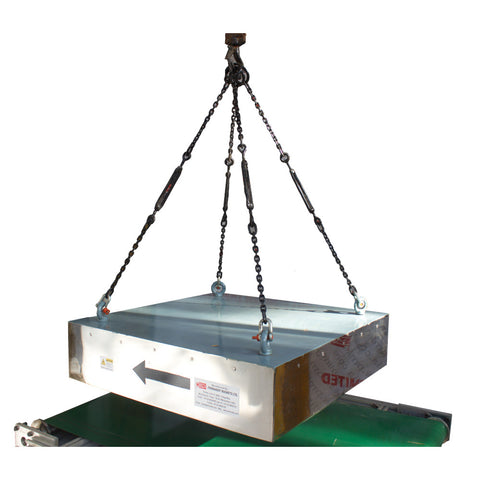

The high-intensity Magnetic Rota Grid Separator has been specially designed to trap/separate the fine iron contamination from the sticky material or from the material with some amount of moisture content. These are used in Food, Chemical & Pharma industries.

Generally, the sticky powdered material is not free-flowing material & forms lumps. These lumps lead to bridging phenomenon thereby blocking the further flow of material when fixed type rod grids are used. The Magnetic Rota Grid separator overcomes this deficiency as the Rota Grid assembly rotates & does not allow the material to form lumps / Bridge.

All powders & granular type materials can also be processed through the unit effectively

Construction:

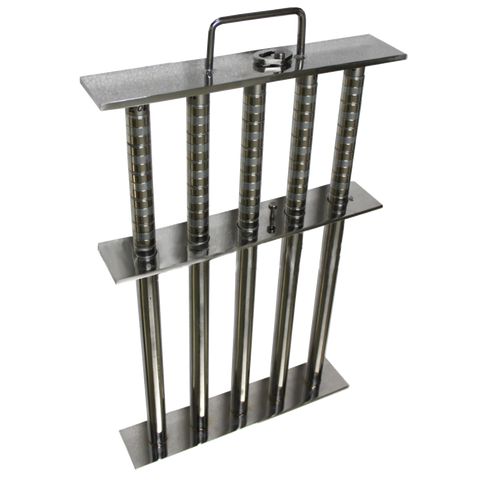

Magnetic Assembly comprises of centrally mounted Rota grid. Rota grid is an assembly of magnetic rods arranged around the periphery. This rota grid assembly is coaxially mounted on a rotating shaft. All this assembly is enclosed in a Housing.

The rota grid assembly is directly mounted on gear drive. The gear drive assembly is outside the housing. Please see the below image of assembly.

High-Intensity Magnetic Rota Grid System Permissible Max. Operating Temp. 80ᵒC

(Peak flux density value 11,000 ±500 Gauss, When measured on magnetic pole surface)

| High-Intensity Magnetic Rota Grid Separator | ||||||

|---|---|---|---|---|---|---|

| Model No | Inlet / Outlet Dia.(mm) | Total HT.(mm) | kW Rating | No. of Magnetic Elements | ||

| MRGS - 1 | 150 | 400 | 0.37 | 5 | ||

| MRGS - 2 | 200 | 450 | 0.37 | 6 | ||

| MRGS - 3 | 250 | 500 | 0.37 | 7 | ||

| MRGS - 4 | 300 | 550 | 0.37 | 9 | ||

| MRGS - 5 | 350 | 600 | 0.37 | 10 | ||

| MRGS - 6 | 400 | 650 | 0.37 | 13 | ||

| Dimensions of Inlet & Outlet Connecting Flanges | ||||||

|---|---|---|---|---|---|---|

| Model No | Flanges O.D.(mm) | Hole Dia. (mm) | No of Holes | Hole PCD(mm) | Flange THK.(mm) | |

| MRGS - 1 | 279.4 | 22.2 | 8 | 241.3 | 6 | |

| MRGS - 2 | 342.9 | 22.2 | 8 | 298.4 | 6 | |

| MRGS - 3 | 406.4 | 25.4 | 12 | 361.9 | 6 | |

| MRGS - 4 | 482.6 | 25.4 | 12 | 431.8 | 6 | |

| MRGS - 5 | 533.4 | 28.6 | 12 | 476.2 | 6 | |

| MRGS - 6 | 596.9 | 28.6 | 16 | 539.7 | 6 | |

Note :

- Customized designs of Magnetic Rota grid separators are available.

- Magnetic Rota grid separators are also available with peak 10000 Gauss for operating temperature up to 150ᵒC & with peak 9000 Gauss up to 200ᵒC.

Working Principle

The inlet of the Magnetic Rota grid separator is connected to the duct or hopper through which material will enter into the separator (Please refer to the above schematic drawing). Further, the material will fall on to the rotating Magnetic Rota Grid which is driven by the motor. Rota grid separates/traps the iron contamination embedded into the lumps of material.

Due to the rotating mechanism, the Rota grid does not allow the material to bridge or form lumps. This facilitates the flow of material & it easily comes out from the outlet of the separator.

The iron contamination will stick on to the Magnetic rods of the Rota grid & the OK material can be collected from the outlet.

Cleaning

To clean, simply open the door of housing & unlock the grid mounting nut. Take out the magnetic Rota Grid from the housing. Now swipe the all contamination from the magnetic rods with the help of a cloth.

Product Features

- Best suitable for processing stick material.

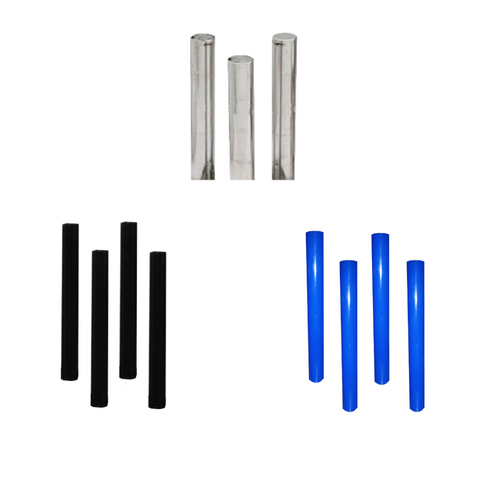

- High power Rare earth (NdFeb) magnets with peak 10500 Gauss on poles of the magnetic rod.

- This effectively catches the micron level of iron contamination.

- These are available with MOC of either SS304 or SS316.

FAQ for Magnetic Rotagrid Separator

- 1) How to clean the magnet?

- Ans - The magnetic rods are provided on the rotating shaft. To clean the iron, Open the door & wipe our the iron with the clothes. The catched iron on the magnetic plate can be remove by wiping the clothe manually.

- 2) How to install the Rotary magent?

- Ans - The ASA standard flanges are provided at inlet & outlet to install the magnet into process line

- 3) In what direction magnetic hump should be installed?

- Ans - Vertical direction only.

- 4) Is it leak proof?

- Ans - Yes. Gaskets are provided at magnet opening to prevent material leakage.

- 5) Does it require power supply?

- Ans - Yes, Center shaft on which rods are mounted rotates with the help of the induction motor.

- 6) Where it is used?

- Ans - Rotary Magnet is used to separate iron from sticky, slurry & non free flowing materials. This will help for better iron removal from material.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 9) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 10) How should i select the magnet size?

- Ans - Please select PML standard model as per material flow rate & type of iron contamination.